NEW ADVANCEMENTS IN AN OLD SCIENCE

WHO CAN BENEFIT FROM LABCHECK NEXT GENERATION?

ONE PROGRAM, MANY BENEFITS

- Identify and measure lubricant conditions and contamination

- Assess equipment conditions

- Prevent breakdowns

- Maximize equipment uptime

- Maximize component lifespan

- Reduce fuel and oil consumption

- Decrease operational costs

- Eliminate unnecessary overhauls, in-service failures, and field repairs

- Establish optimal drain and service schedules

LABCHECK NEXT GENER ATION : A NEW GENER ATION OF SERVICE, PERFORMANCE, AND INNOVATION

- Locate sample information using search fields

- Spot items that require immediate attention

- Chart samples by severity

- Track the number of samples from each worksite

- Review turnaround times

- Monitor first signs of critical wear

POWERFUL, FLEXIBLE, FAST

- Customize your home page with moveable/ removable elements

- Locate real-time and historical sample results using “Quick Search” functions

- Quickly view the status of any sample with our easy-to-read sample formats

- Download and send sample data as an email with additional maintenance feedback

- Create special “alerts” on critical units

- Use the enhanced graphing tools to select data from assorted criteria and create custom graphs — then incorporate them into reports

- Forecast and predict potential problems using the versatile new trending tools

- Customize alarm limits to meet your specific criteria

- Customize terminology to match your company’s unique business terms

- Use the hierarchy data structure to organize information from the worksite level, to the unit level, to the compartment level

- Create compartment comparisons across an entire fleet of equipment

- Manage, update, move, and even rename individual pieces of equipment

- Use the historical data records to identify where a unit has been and what samples were taken at previous locations

- When the unit moves to a new worksite, all samples taken at previous locations move with it — eliminating data fragmentation

- Use the new reporting tools to make the task of generating reports easier and faster

- Display reports in PDF formats that can be emailed, printed, or saved

- Determine how reports are generated in terms of data content and how they are sent out — either as an email attachment, jpg file, or hard copy

- Use the convenient online label feature to generate one or multiple Avery Labels with optional bar code functionality

- Add, modify, or delete users (and user groups). Grant user access to data and then control what can be done with the gathered data

- Create specialized Program Management and Summary Reports to help manage and control your oil sampling program. These reports compile information on Critical Conditions, Condition Analysis Statistics, Sampling Summaries, and other factors

ONLY ONE COMPANY PASSED OUR LAB TEST

EXPERIENCE Analysts, Inc. was founded in 1960. With over 50 years of experience, they’ve led the industry in developing innovations in testing, analysis, and service.

EQUIPMENT Analysts operates five laboratories in the U.S., all equipped with today’s most advanced instruments. Many are automated and interface directly with the lab’s computer system to ensure accurate and rapid turnaround service.

STAFF Accurate testing begins with a well-trained staff — and more of Analysts staff members are STLE Certified personnel than any other commercial oil analysis lab.

QUALITY CONTROL Analysts has created one of the strongest registered ISO 17025 quality programs in oil analysis. Their quality-assurance program meets the requirements of 10 CFR 50, Appendix B — the federal specification for quality programs in nuclear power plants.

SERVICE Analysts’ exceptional documentation, training, accuracy, and follow-up have established them as the industry’s recognized leader in quality and service.

RAPID TURNAROUND Analysts’ average turnaround time is 24 hours or less for routine samples. Over 80% of the samples they receive are completed the same day they arrive.

RESPONSIVE ACTION When critical conditions are detected, customers are notified immediately. Sample reports are available online the moment they are completed. Tests that indicate the need for a major inspection are double-checked prior to your notification. Customers can receive sample results online or by email alerts.

INNOVATIVE TESTING, COMPREHENSIVE SERVICE

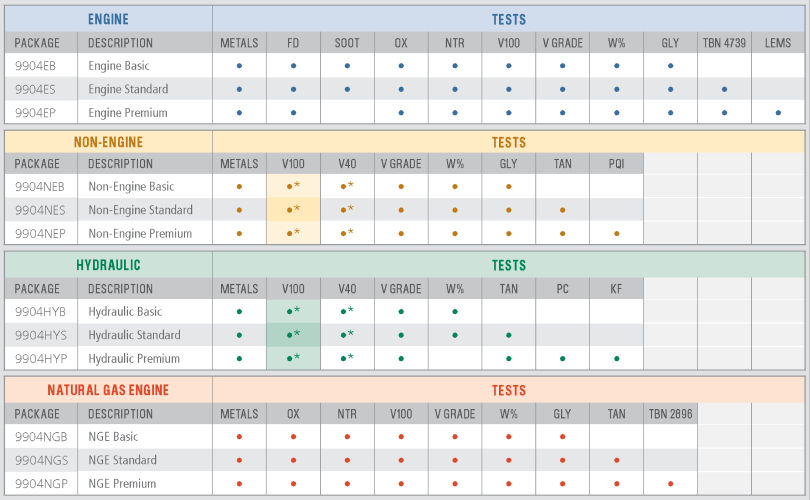

WEAR METALS Wear metals are tested to help locate premature wear and component risk. Labcheck Next Generation wear metal tests look for an abnormally high presence of silver (Ag), aluminum (Al), chromium (Cr), copper (Cu), iron (Fe), molybdenum (Mo), nickel (Ni), lead (Pb), tin (Sn) and other metallic elements—monitoring a total of 21 distinct metals.

CONTAMINANT METALS Contaminant metals are monitored in each sample to detect contamination of the fluid in specific compartments. Fluid contamination can cause components to lose efficiency.

VISCOSITY Viscosity is tested to detect a change in the oil’s fluid properties. High viscosity promotes overheating in equipment, restricted oil flow, accelerated wear, impeded low- temperature operation, increased friction, and increased fuel/power consumption. Low viscosity promotes overheating, metal- to-metal contact, accelerated wear and increased lubricant leakage. Changes in viscosity can be the result of other problems in the sampled compartment.

FUEL DILUTION Used oil is tested for the presence of unburned fuel. Using oil diluted by fuel can lead to rapid and catastrophic component failure due to reduced viscosity and film strength, as well as increased wear, and the possibility of a fire hazard.

SOOT Soot can cause a host of problems, including poor engine performance, decreased fuel economy, increased wear, shortened fluid life, deposit and sludge formation, clogged filters, and increased operating costs. This test measures the soot content of used engine oils and flags every sample containing 5% soot or higher.

GLYCOL (ANTIFREEZE) Antifreeze in any compartment other than the cooling system is a critical problem and can lead to rapid and catastrophic component failure. This test looks for and reports the presence of glycol in components.

WATER This test looks for the presence of water, performing moisture checks for coolant leaks or condensation formation. Water contamination can promote acid formation, which can cause components to lose efficiency.

LABCHECK NEXT GENERATION OPTIONAL TESTS

OXIDATION & NITRATION Excessive oxidation can cause increased wear, decreased engine performance, shortened equipment life, deposits, oil-filter plugging, increased oil viscosity, corrosion of metal parts, increased acidity in oil, and restricted oil flow. Heat and oxygen in oil can cause it to break down. Low crankcase oil temperatures accelerate the rate of nitration. By-products cause accelerated oil thickening, formation of acidic by-products, increased cylinder and valve train wear, combustion-area deposits, increased acidity in oil, and accelerated sludge formation. Our oxidation & nitration test looks for evidence of all these elements, including the presence of nitrogen by-products, which can accelerate oil breakdown.

ACID NUMBER Increases in the acid number of a fluid may be caused by oxidation, nitration, or contamination. The acid number can determine the serviceability of a lubricant in specific applications. A high acid number may indicate corrosion of metallic components, oxidation, oil degradation, and additive depletion.

BASE NUMBER Engine oil usually begins with a relatively high base number that decreases during use—this is an important factor in establishing oil drain intervals. By monitoring the base number, the potential for oil degradation, increased wear, and corrosion of metal parts can be detected.

PARTICLE COUNTING (HYDRAULIC, TURBINE, AND TRANSMISSION FLUIDS)This test measures the cleanliness of an oil by determining the level of contaminants. Utilizing two extremely accurate methods, particles over two microns in size can be detected. By closely monitoring the particle size and count in a fluid, maintenance professionals can detect wear-causing abrasion at the onset and correct conditions that can cause the level of particulate matter to increase.

FERROGRAPHY This test quantifies larger particles that cannot be seen by standard used oil analysis equipment and can correlate them to a problem in the system. Ferrography is typically run for forensic investigative measures to identify the origin and nature of wear or failure mode.

LABCHECK NEXT GENERATION TEST PACKAGES

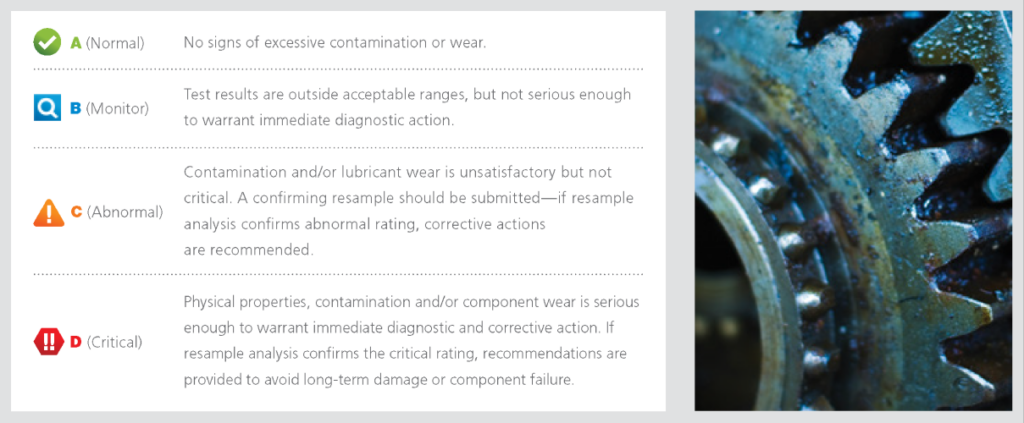

SPOT PROBLEMS, TAKE ACTION

AT YOUR SERVICE

MAKE LABCHECK NEXT GENERATION PART OF YOUR LONG-TERM MAINTENANCE PROGRAM

GETTING STARTED IS EASY

FOR TECHNICAL SUPPORT

The Castrol Labcheck Support Desk provides industry-leading program and technical support. The support desk can be reached toll-free at 866-LABCHECK (522-2432) from 7:00 am - 6:30 pm CST.