Offer Summary - Shell

Lube Optimiser – On site Lube management and services

Lube Optimiser – On site Lube management and services

- Shell LubeOptimiser is an end-to-end solution designed to help companies address common challenges, such as simplifying operations, reducing downtime, and protecting equipment.

- Together with our network of on-site reliability service providers, we help companies with:

- Maintenance support and troubleshooting activities during the lifetime of your machinery oil

- Expertise to identify areas of improvement to help avoid unexpected disruptions and increase uptime

- This can help tackle issues such as:

- Loss of Productivity - Contamination is a leading cause of equipment breakdown, which in turn leads to enormous productivity losses.

- Lack of Manpower – Effective lubrication management is challenging when companies face a lack of field expertise, tools and processes. We can help.

- Missed Opportunities - Supplier complexity can create unnecessary inefficiencies and lost opportunities. Shell LubeOptimiser is your one-stop- shop.

- Primary services :

- Filtration

- High velocity Oil flushing

- Dehydration

- Initial fill services

- Reclamation

- Cleaning

- Varnish removal or mitigation

- Additional services could include – Equipment Sale / Lease, Chemical cleaning, Hydroblasting, Oil mist system, Oil system preventive maintenance

Remote Sense – online oil condition monitoring

Remote Sense – online oil condition monitoring

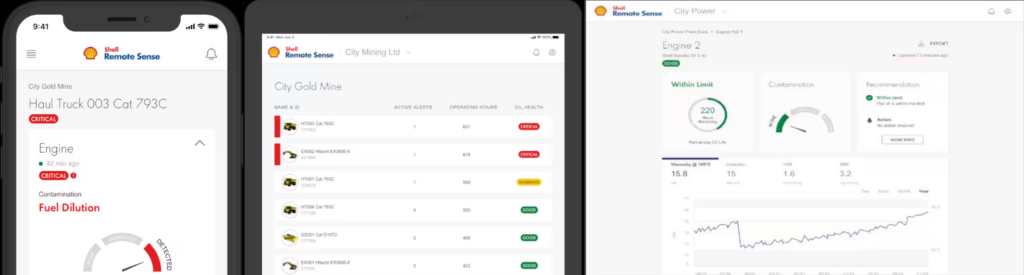

- Shell Remote Sense is an online oil condition monitoring service that uses sensor data and advanced analytics to deliver actionable insights about the condition of your oil.

- The insights are delivered in real-time via the Shell Remote Sense website and email alerts, and can be integrated with existing monitoring and telemetry systems via API connections.

- Shell Remote Sense improves upon traditional lab-based oil analysis in that the oil is continuously monitored, allowing you to catch potential problems before they cause damage to your equipment.

- Key elements :

- REAL TIME OIL CONDITION MONITORING

- ACTIONABLE INSIGHTS & RECOMMENDATIONS

- Customer benefits :

- REDUCE UNPLANNED DOWNTIME

- OPTIMISE MAINTENANCE

- EXTEND EQUIPMENT LIFE

- IMPROVE UTILISATION & IMPROVE PRODUCTIVITY

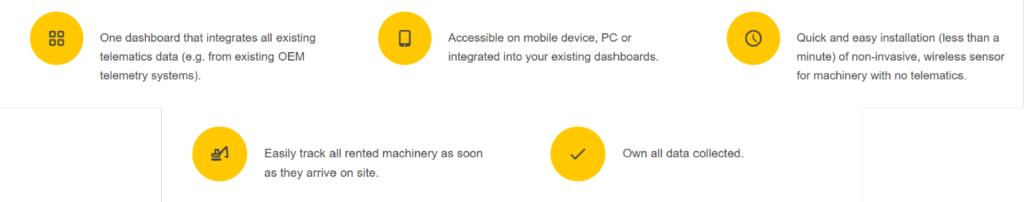

MachineMax - one digital platform to manage all heavy equipment

- MachineMax is a digital equipment management platform for off-highway fleets. Using any available existing data source or smart sensors when required, together with next-generation analytics, it helps companies maximise the utilisation and profitability of their off-highway vehicles.

- Designed to help optimise operations today for a stronger outlook tomorrow, MachineMax enables equipment operators to track an entire fleet of owned, rented, and contracted machinery – regardless of OEM, model, ownership or location.

- Data is collected from vehicles and communicated real-time to operators, to help:

- Increase site productivity by optimising the size and composition of the fleet and removing bottlenecks.

- Reduce costs and engine emissions by increasing utilisation of machines and reducing engine idle times.

- Proactively manage repair and maintenance by automating the optimisation of servicing schedules.

- In this way, MachineMax delivers Increased profitability, by improving productivity and utilisation of equipment and staff and Reduced environmental impact, by lowering emissions and minimising idling times.

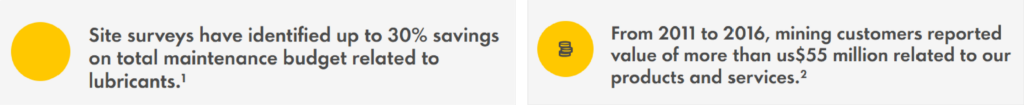

LubeAnalyst – a Labcheck type solution

- Whether you work on- or off-highway, in the power industry, or general manufacturing, preventative maintenance can help unlock savings and cut

unplanned downtime. Oil condition monitoring is an essential part of this. Continually monitoring the condition of oil inside your equipment can provide

an early-warning of impending failures empowering you to stop potential failures in their tracks. It can also help determine appropriate oil-drain

intervals, and help extend equipment life. - Offered as 2 services –

- Conventional laboratory oil analysis and

- Remote sense – online oil analysis

- Both coupled with a digital solution

LubeExpert – Tech services support

LubeExpert – Tech services support

- For over 20 years our experts have supported mining companies around the world in identifying issues and solving problems to minimize down time and optimize productivity. Including a Shell lube expert in your team will help you realize your short- and long-term goals, reducing the total cost of ownership and improve your bottom line

- Shell lube experts have a wealth of mining and engineering expertise gained from decades of working with the leading mining companies in the world. This allows us to leveraee the insights and knowledge to find the best solution to fit your unique business needs.

- Shell LubeExperts

- Integrate with your maintenance teams

- Work on machines and mills

- Bring mining and engineering expertise

- Provide insight and innovative technology from around the world

- Inspect using strobe-o-scope, thermal imaging and vibration analysis

- Audit lubrication systems and injectors

- Perform injector spectrum sleeve fitment

- Optimise grease onto fixed and mobile equipment

- Committed to the long-term

- Our commitment doesn’t end with solving your challenges today, we’re dedicated to assisting your operations become more sustainable for the long-term. We launched the service over twenty years ago and still work with our first customer. At the same time, we’ve developed long-standing relationships with 10 of the top 12 mining companies around the world.

Oren – B2B marketplace for Mining – Is it alive ?

- Oren connects industry leaders with the world’s most innovative solutions from trusted companies and solution providers.

- Designed to help mining companies address their significant pain points, Oren provides a Digital Development Workshop that identifies a company’s key challenges and priorities for investing in digital solutions, then offers insights and digital solutions.

Shell in Australia

- Shell used to operate directly with Australia mining customers till ~ 2010

- With the exception of Rio Tinto, Shell now operates in Australia mining industry through it’s partner – VIVA energy

- Most of the offers projected by Shell are not seen in practice on ground

- Machine Max and Oren are not seen with any customer

- Shell’s lube analysis program is nothing special

- Optimiser is the solution that is seen to some extent – using Viva energy personnel

- As seen from VIVA energy website (vivaenergy.com.au), the offer for mining customers essentially includes –

- Technical Help desk

- Technical advisors

- Shell Lube Match – selection of lubricants

- Shell Lube analyst – lube monitoring services