- Five reasons to choose TE Lubricants TE Mining Services

- 1. LubAnac Off-road – used oil analysis

- 2. Open Gear Drive Cleaning - Fast & Effective

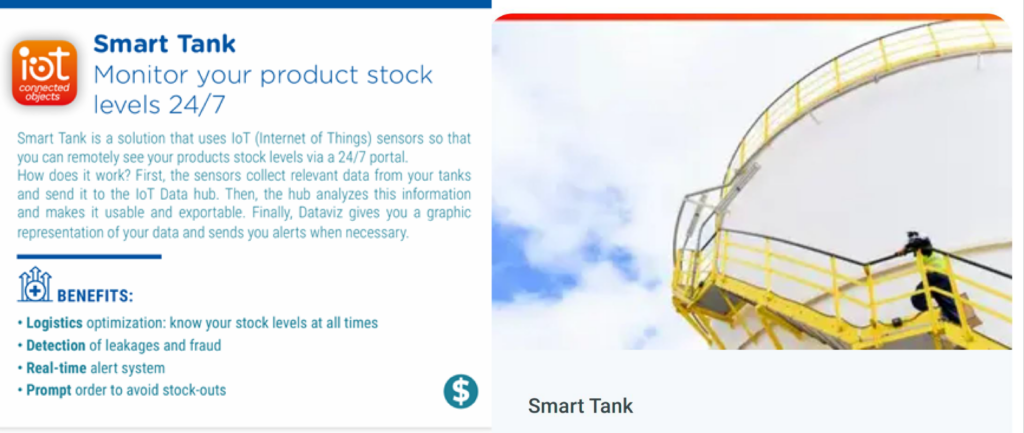

- 3. Online tank monitoring – Smart tanks

- 4. Optimisation of energy consumption

- 5. Training programmes – on lubes, greases and safety

- 6. Maintenance software – to simplify management of maintenance operations

- 7. Filtration solutions

- TotalEnergies Commitments - designed a range of solutions to address 5 areas of need.

- Mining Energy Solutions

- Commitments

- TotalEnergies Commitments

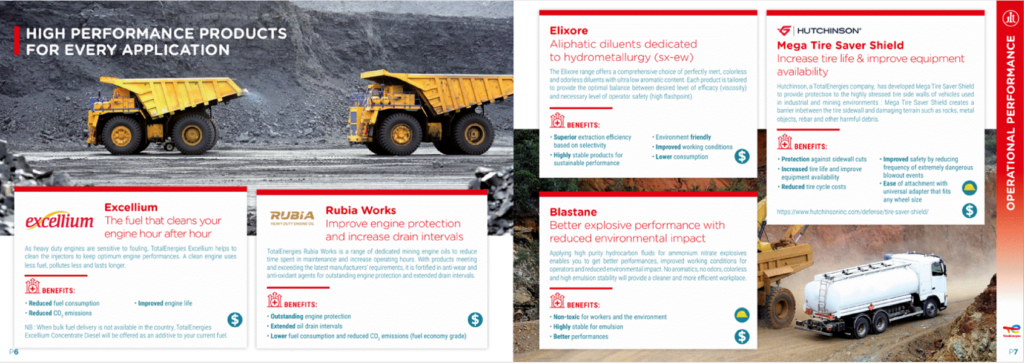

- High Performance Products For Every Application

- Continuous Support Ensuring Peace of Mind

- Advanced Solutions to Reduce your TCO even more

- Offgrid Solar Solutions

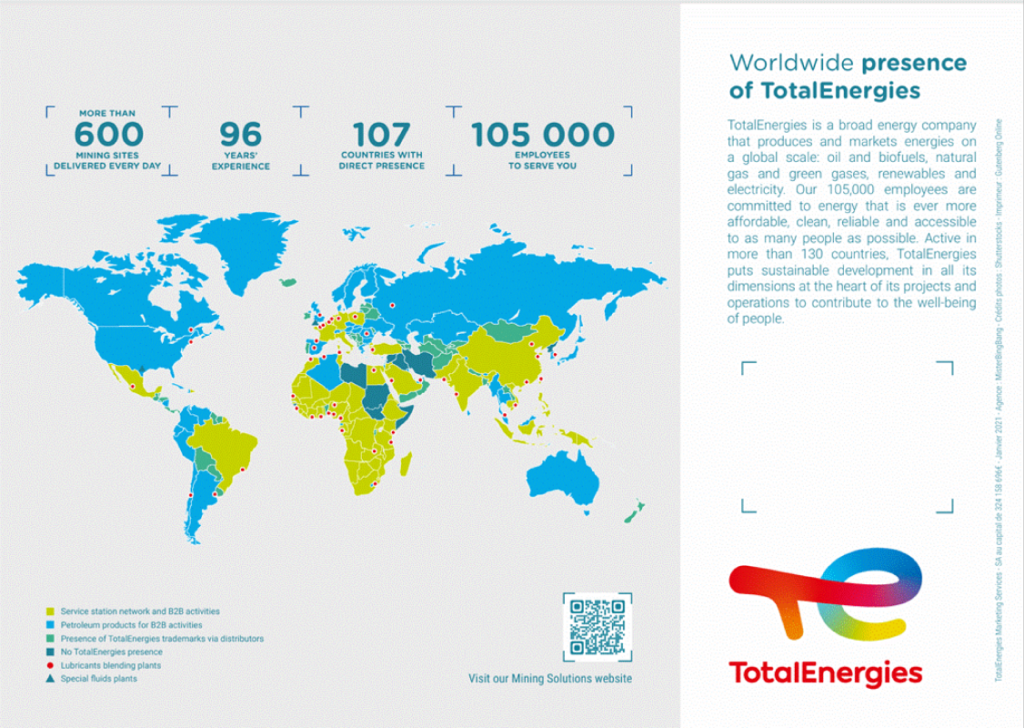

- Worldwide Presence Of TotalEnergies

- Mining Lubrication & Services

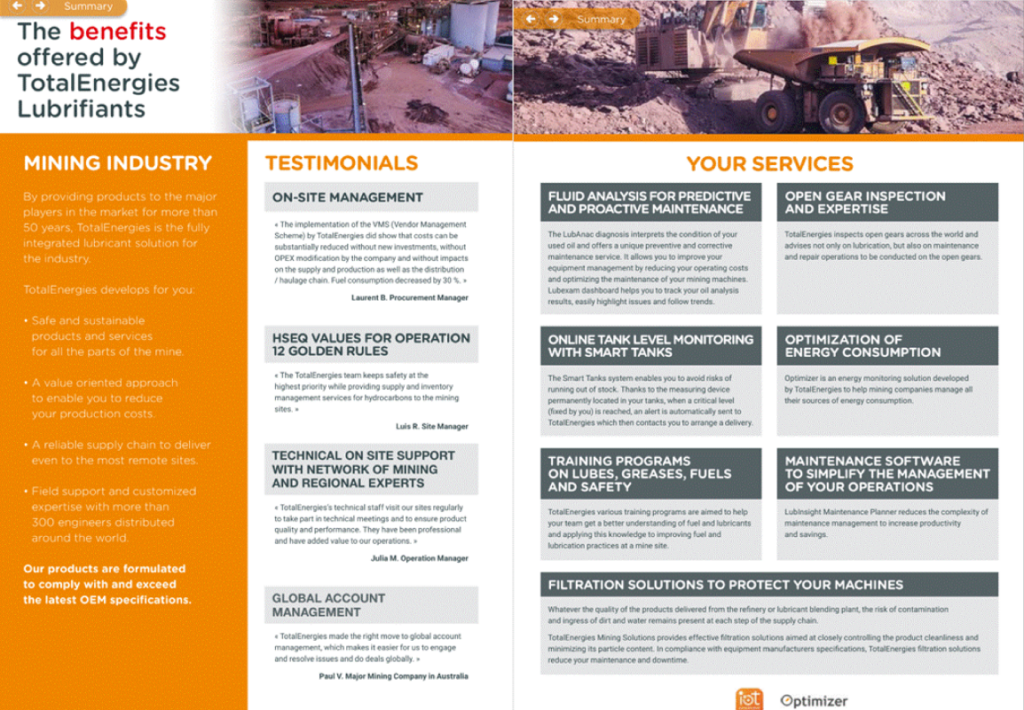

- The benefits offered by TotalEnergies Lubrifiants

- Boost Your Productivity and Reduce Your Maintenance cost with field proven solutions

- Open Gear Drive Cleaning - Fast & Effective

Five reasons to choose TE Lubricants TE Mining Services

1. LubAnac Off-road – used oil analysis

What is the TotalEnergies ANAlysis Compared system?

LubAnac is a preventive maintenance tool, and fleet management system

based on used oil analyses ensuring significant reduction of customer TCO:

- Prevents possible breakdowns

- Regularly monitors lubricant condition & mechanical component wear.

- Extends the lifetime and the reliability of the machines

- Optimizes drain intervals in a safe way.

LubAnac diagnosis service sold worldwide by TotalEnergies affiliates

LubAnac is an OFF-ROAD specialist

Diagnosis & corrective actions generated by LubAnac off-road system:

- 40 years data input into the LubAnac database

- <7m analysis on 1m components

- Customer feedback on successful corrective actions

- A comparison between the measured values and the wear references based on algorithms

2. Open Gear Drive Cleaning - Fast & Effective

Open Gear Drive Cleaning

Open gears used in rough mining environments are affected by abrasive particles such as clinker, coal dust, sand, metallic powder.

Cleaning very large pieces of machinery is a difficult and time-consuming process, increasing downtime and maintenance costs.

Lubriclean EP is a fast and cleaning solution.- The cleaning team can conduct cleaning without production shutdown.

- It helps prevent abrasive wear impact and extends mining equipment life

Key Benefits

- Can be used while gears are in operation, reducing costly downtime

- One-hour simple cleaning vs 48 hrs conventional cleaning – cuts costs.

- Removes grease, dust, lacquer and dirt, leaving gears

- Non-toxic & biodegradable, no chlorine, aromatics or volatile organic compounds, keeps operators and environment safe

- Lubriclean EP slowly evaporates, leaving a high-performance film that withstands extremes of pressure

3. Online tank monitoring – Smart tanks

4. Optimisation of energy consumption

5. Training programmes – on lubes, greases and safety

6. Maintenance software – to simplify management of maintenance operations

7. Filtration solutions

TotalEnergies Commitments - designed a range of solutions to address 5 areas of need.

High HSE Standards - TotalEnergies SAFETY RULES

- 12 HSE Golden Rules - Transport security program (Patrom) - Waste management - HSE Audit - Safety Training

Reliable Supply

- International network of experts - Change Management - Field Operations - Mining expertise

- Management - Consignment stock - Depot management - In-pit services - Used oil analysis (LubAnac) - Maintenance software (TIGS) - Filtration solution to ensure product cleanliness

- Training your teams - Gain in-field skills

- Modular, mobile and flexible offer - Fixed, mobile and temporary tanks

- Quality warranty - ISO certifications - International standards (API, JASO, etc...) - OEM approvals

Cost improvement (TCO) & Energy efficiency

- Support in the Value Chain optimisation - Multi-Energy Management (Optimizer) - On-site cost control and energy

consumption software - Used oil analysis (LubAnac oil diagnosis) - Stock management - Lubricants rationalization - Choice of suitable products - Fuel Economy lube (reduced consumption) - Rubia Works (extended drain interval) and off

road lubricants - Industrial lubricants - Lubriclean EP for open gears - Stakeholder training - Better use so less waste

Reduced environmental impact - REDUCED CO2 EMISSIONS

- Biolubricants

- Energy Efficiency

- Product

- RRBO

Innovation & Digital tools - INNOVATIVE SOFTWARES TO OPTIMIZE PROCESSES

- Multi-Energy management (Optimizer)

- Where Is My Truck?

- Monitor your stock (Smart Tank)

- Used oil analysis (LubAnac oil diagnosis)

Mining Energy Solutions

Commitments

TotalEnergies Commitments

Value adds

- 12 Golden Safety rules

- Reliable supply of high-quality products and services – Network – Management (consignment stock, UO, Maint software, tanks, quality warranty)

- TCO Cost improvements – value chain – Environmental – products – digital tools

- Depot storage build and management – lubes and fuel

High Performance Products For Every Application

- Lubricant product – cleans –protects – increase drain

- Explosives additives

- Tyre saver – side wall protection

Continuous Support Ensuring Peace of Mind

Services

- Fluid cleanliness and contamination management

- ANAC Oil Diagnostics – with predictive maintenance

- HSE Audits – full supply chain and operations

- Safety training

Advanced Solutions to Reduce your TCO even more

- Fuel economy lubricant range

- Lubriclean

- Optimizer

- Smart Tank

- Real time delivery tracking

- Energy audits

- Renewable energy solutions

- Saft batteries

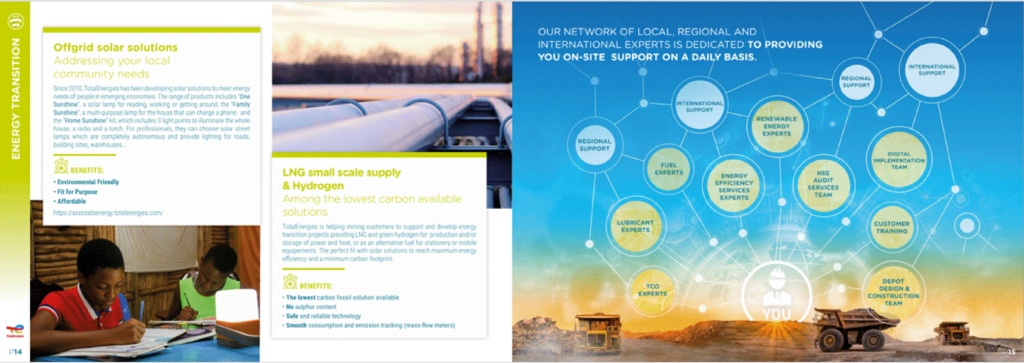

Offgrid Solar Solutions

- Offgrid solutions

- LNG/ Hydrogen supply

Worldwide Presence Of TotalEnergies

Mining Lubrication & Services

The benefits offered by TotalEnergies Lubrifiants

Boost Your Productivity and Reduce Your Maintenance cost with field proven solutions

Open Gear Drive Cleaning - Fast & Effective

Open Gear Drive Cleaning

Open gears used in rough mining environments are affected by abrasive particles such as clinker, coal dust, sand, metallic powder.

Cleaning very large pieces of machinery is a difficult and time-consuming process, increasing downtime and maintenance costs.

Lubriclean EP is a fast and cleaning solution.- The cleaning team can conduct cleaning without production shutdown.

- It helps prevent abrasive wear impact and extends mining equipment life

Key Benefits

- Can be used while gears are in operation, reducing costly downtime

- One-hour simple cleaning vs 48 hrs conventional cleaning – cuts costs.

- Removes grease, dust, lacquer and dirt, leaving gears

- Non-toxic & biodegradable, no chlorine, aromatics or volatile organic compounds, keeps operators and environment safe

- Lubriclean EP slowly evaporates, leaving a high-performance film that withstands extremes of pressure