Fuchs Mining Offer Tailor-made Service And Maintenance – Worldwide

You can rely on the strength of our technical and service

excellence, and our global network of specialists in all

key mining locations.

With our range of services, we ensure that our lubricants perform at the highest level and allow for your

machine to run reliably and efficiently. Our expertise in this field contributes to longer maintenance

intervals, reduced consumption, longer lifetimes of machines and, as such, to the sustainability and

environmental strategies of mining operators.

Our local experts contribute to the performance, efficiency and process

reliability of your entire application through their broad process-spanning

expertise and on-site technical consultation. Whether you want specialist

advice with a view to reducing your number of lubricants, longer lubrication

intervals or the perfect Open Gear services, we provide you with precisely

the support you need to further optimise your use of lubricants.

Running-in of new open gears

- Running-in and repairs of Open Gears

- Condition monitoring of gear drive bearings and other highly loaded parts

- Grease and oil analysis

- Extensive online reporting

- Further services, such as the checking of lube systems, temperatures vibrations, and load patterns with infrared images and videos

Specially trained service engineers assist with the

commissioning and running-in of new open gears. They

ensure that the drive is run-in optimally according to the

principle of the LUBRITECH MULTI-PHASE LUBRICATION

(M-P L) with accurately defined application quantities of

the appropriate CEPLATTYN adhesive lubricant.

FUCHS LUBRITECH Open Gear inspection procedure

- Visual check of Open Gear and surrounding conditions

- Pinion and girth gear check

- Vibrations on the pinion bearings

- Temperature conditions on the pinion bearings

- Temperature conditions on the mill/kiln shell

- Check of the spray system

- Inspection of spray and pump equipment

- Temperature conditions across the surfaces of the pinion and girth gears

- Quantity determination of the lubricant

- Documentation of the result in the FLT INSPECTOR online system

Service – Inspection and Repair

Regular inspection of Open Gears

For drive units that are lubricated with CEPLATTYN, our

service engineers carry out regular inspections over the

entire service life. They make written notes of the general

operational status, ascertain the amount of wear on the

load-carrying tooth flanks, check the spray lubrication and,

if necessary, reset it. In addition, the service engineer takes

extensive measurements (oscillation speed, flank tempe-

rature, etc.), which are recorded in the FLT INSPECTOR, a

modern documentation system, and are always available

to our customers.

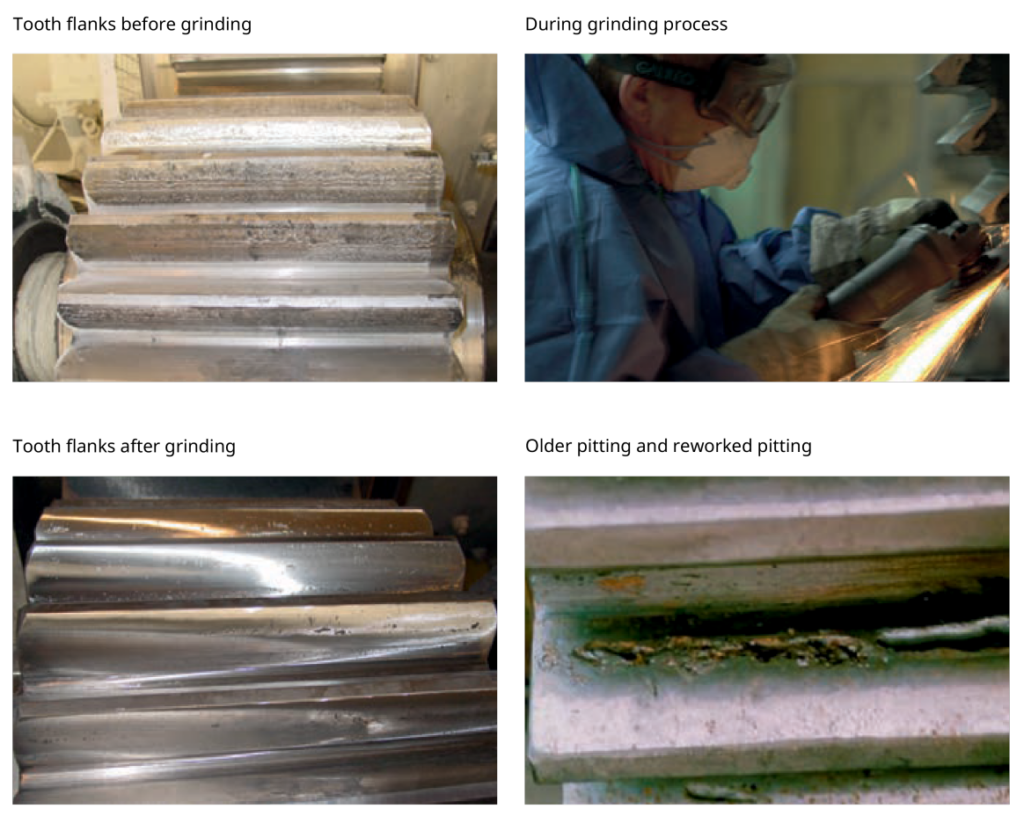

Repair service

The repair of damaged tooth flanks on Open Gear drives is

part of the extended service offered by FUCHS LUBRITECH.

Such repair work is primarily a matter of the mechanical

treatment of the working tooth flanks by grinding pit-

tings or larger breakages, smoothing scuffings, forced

running-in and assistance with alignment of the

transmission gears. On heavily worn-out or damaged

tooth flanks FUCHS LUBRITECH can provide complete

reprofiling of the entire gear set.

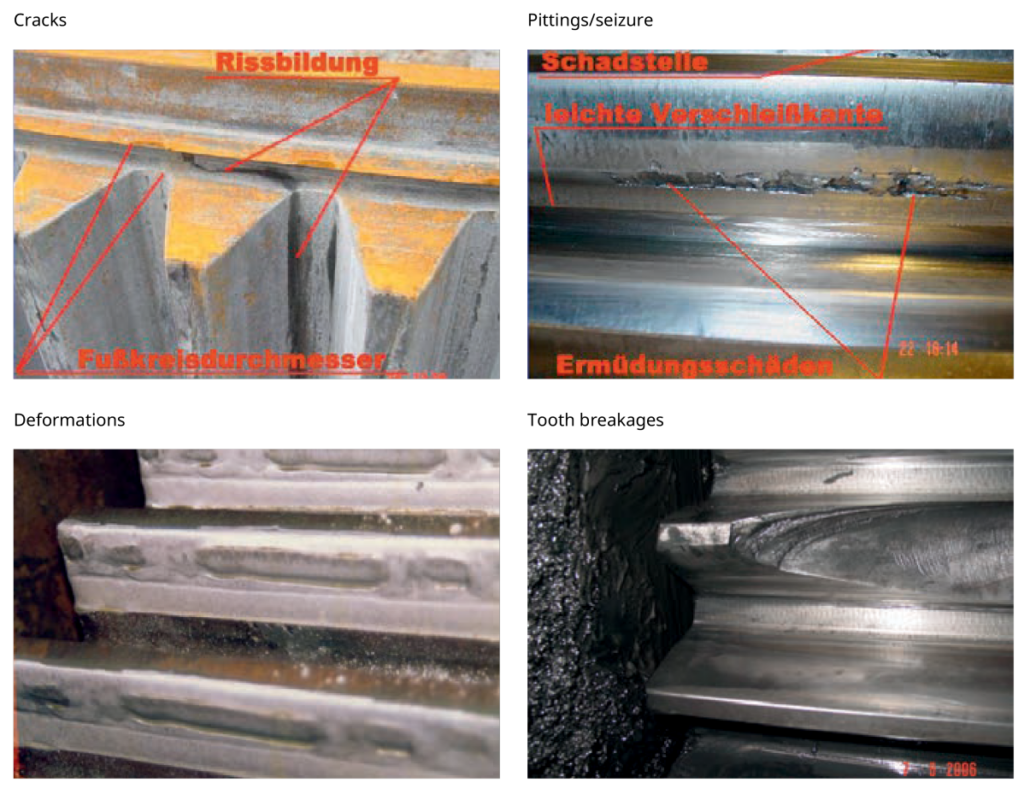

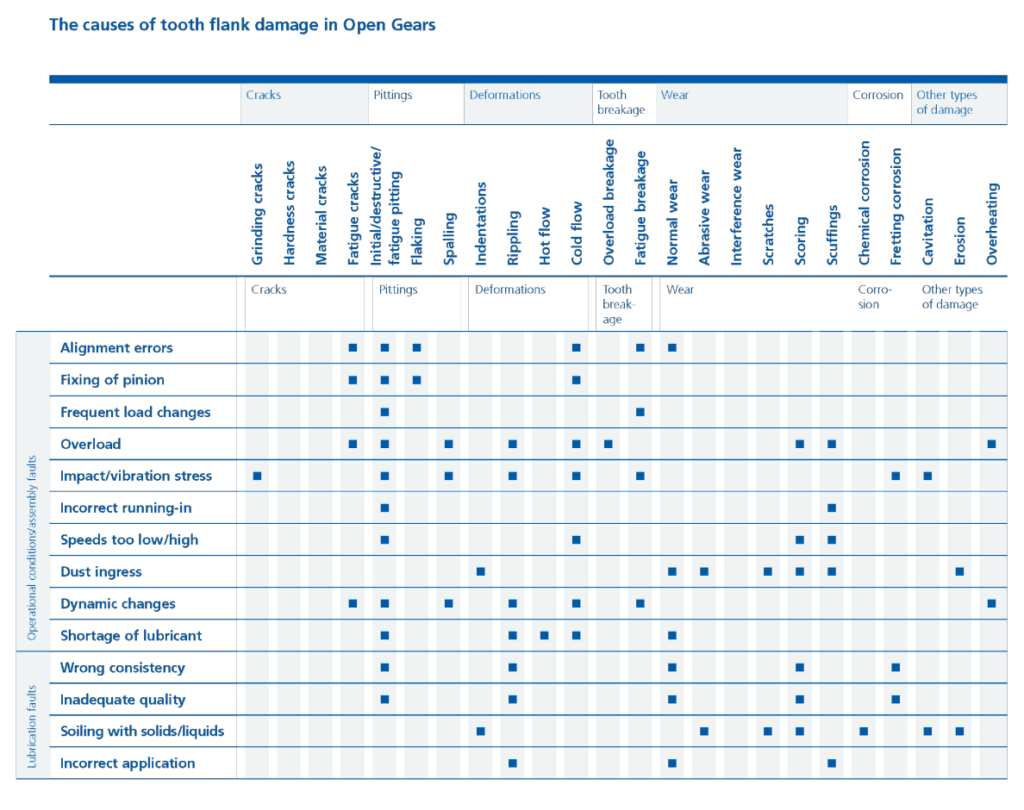

Tooth flank damage and its causes in Open Gears

Gears in a wide variety of designs provide movement throughout the industry. If a gear wheel suddenly stops, the causes can differ considerably. Statistically speaking, damaged tooth flanks account for about 60 per cent of gear drive defects.

The correct lubricant eliminates many damage causes.

It does not matter whether a light oil or an adhesive

lubricant is under consideration. Nor does it matter

whether it is a high-speed vehicle gearing or a low-speed

Open Gear drive: whenever teeth mesh the appropriate

lubricant is one of the most important factors for smooth

operation. Scuffings and abrasive wear, for example, can

be influenced to a large extent by the lubricant. A poor-

quality lubricant also has a direct adverse effect on the

occurrence of fretting corrosion, scoring and scuffings.

The consequences of a lack of lubricant usually include

increased wear or deformations such as the development

of rippling and hot or cold flow. The chart below gives a

basic overview of the problems that can be experienced.

Re-conditioning service

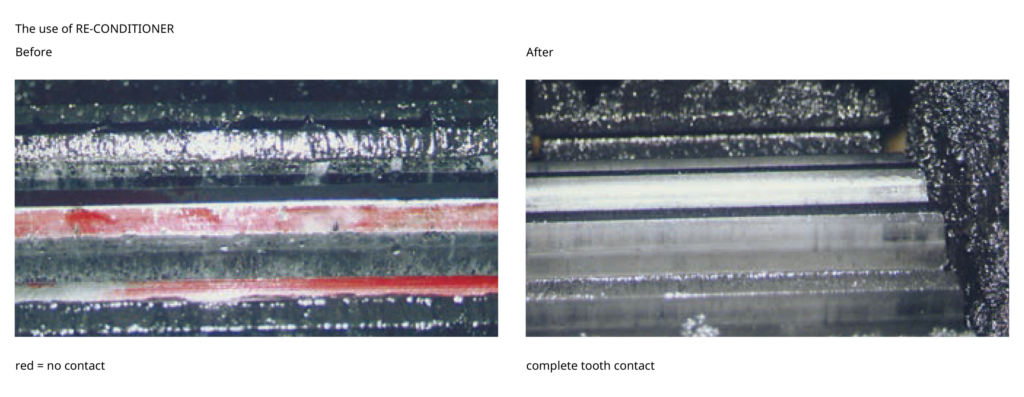

Forced running-in with RE-CONDITIONER

In cases where normal running-in does not result in a

sufficient contact pattern or the drive has to be run in

at full load, a forced running-in (the quick running-in

method) represents the best solution. This forced running-

in procedure is also suitable for achieving an optimum

load-carrying capacity and surface finish if the load-

carrying surfaces show scuffings. In case a new pinion

is installed in combination with an old girth gear

Re-Conditioning is used to reprofile the old girth gear

with the new profile of the pinion. Forced running-in

involves a service lubricant known as RE-CONDITIONER

being manually applied to the working surfaces in

addition to the regular CEPLATTYN RN lubricant during

production. This RE-CONDITIONER effects a smoothing of

the working surfaces within in a shorter time, thus

tremendously reducing the running-in time.

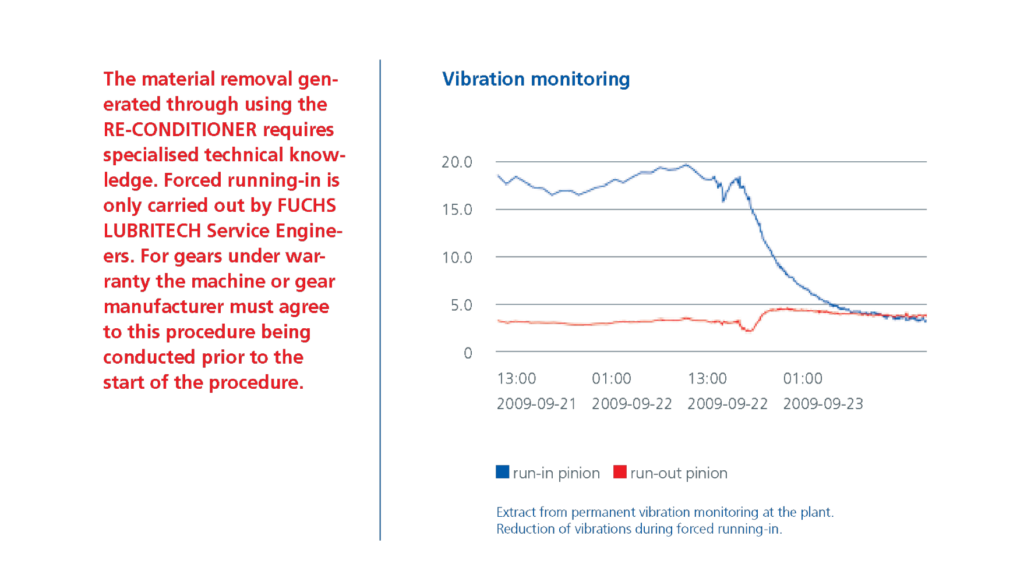

Case study: smoother running after Re-Conditioning

When restarting a helical, double-pinion cement mill small

deviations in axial and radial run-out of the girth gear had

the effect of high vibration differences between the

pinion bearings. At the run-out pinion the vibration levels

were well below 2 mm/s, but they were above 8 mm/s at

the run-in pinion. The operator could not accept this large

difference. Even after several corrections of the trans-

mission gear no improvement was achieved. The

manufacturer of the machinery therefore initiated a

forced running-in. The application of RE-CONDITIONER for

nine hours resulted in a carefully controlled redistribution

of the load: the vibrations of both bearings were

eventually below 2 mm/s. Result: a smooth operation.

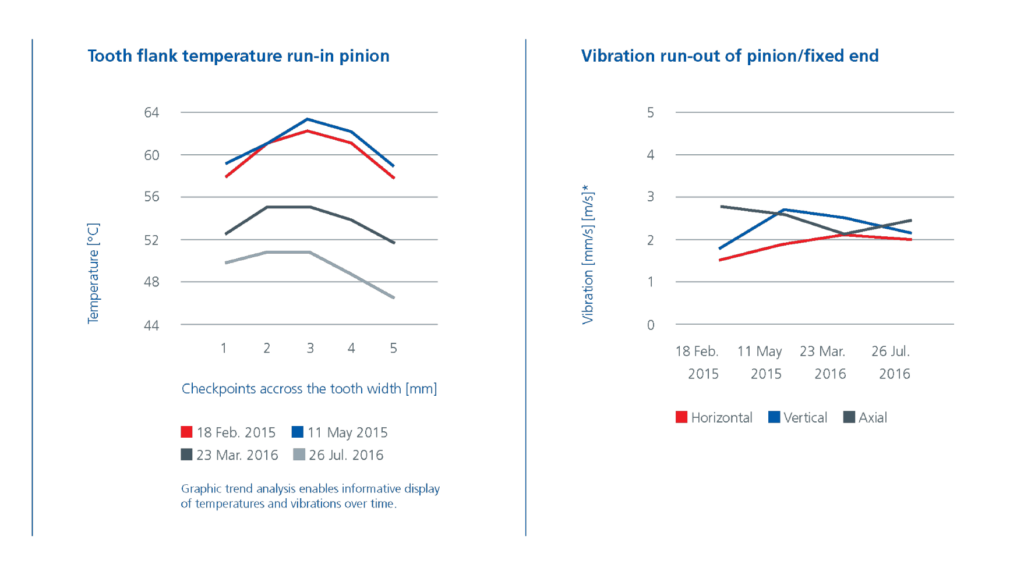

FLT INSPECTOR – online documentation

With the FLT INSPECTOR, FUCHS LUBRITECH is making a unique online

documentation database with an integrated, graphical trend analysis

available that enables the customer to retrieve all relevant information on

their system and the lubricants used at any time.

The open gear service, combined with the online provision

of inspection reports, is a further step towards being able

to operate open running drives reliably.

Your benefits with the FLT INSPECTOR

- Availability of all reports at a glance

- Online access at any time

- Instant check via a traffic light system

- Graphical trend analysis for temperatures and vibrations

- Rapid transmission of data and reports

- Individual access hierarchy

- Optional extra information (attachments) for each inspection report

- App solution for mobile devices