The location and status of the equipment are displayed visually on a map. The load and haul

operational zones and locations are pre set up based on the defined scope of the mine/quarry.

The equipment status is viewed by location and zone, enabling tracking of each piece of equipment.

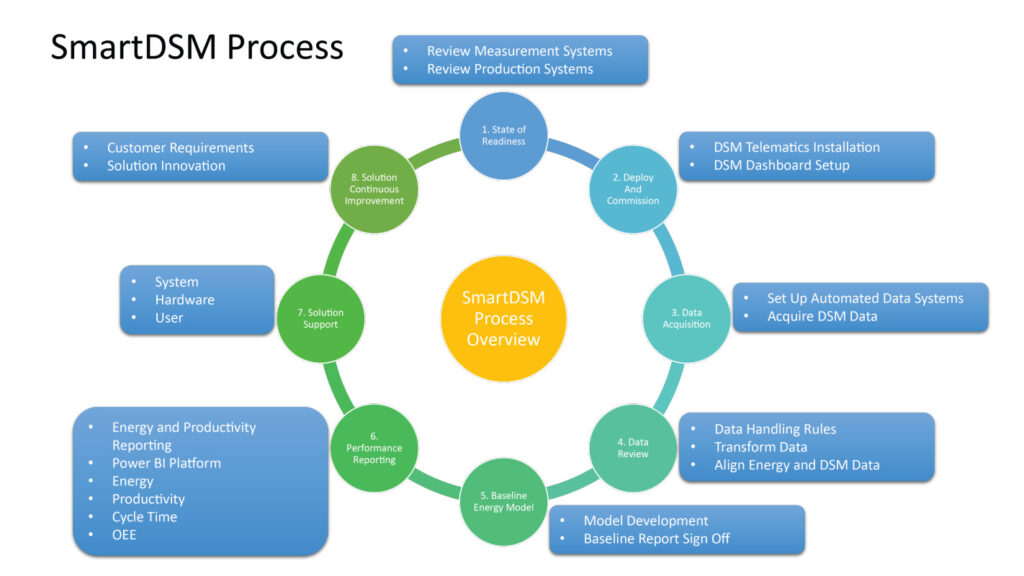

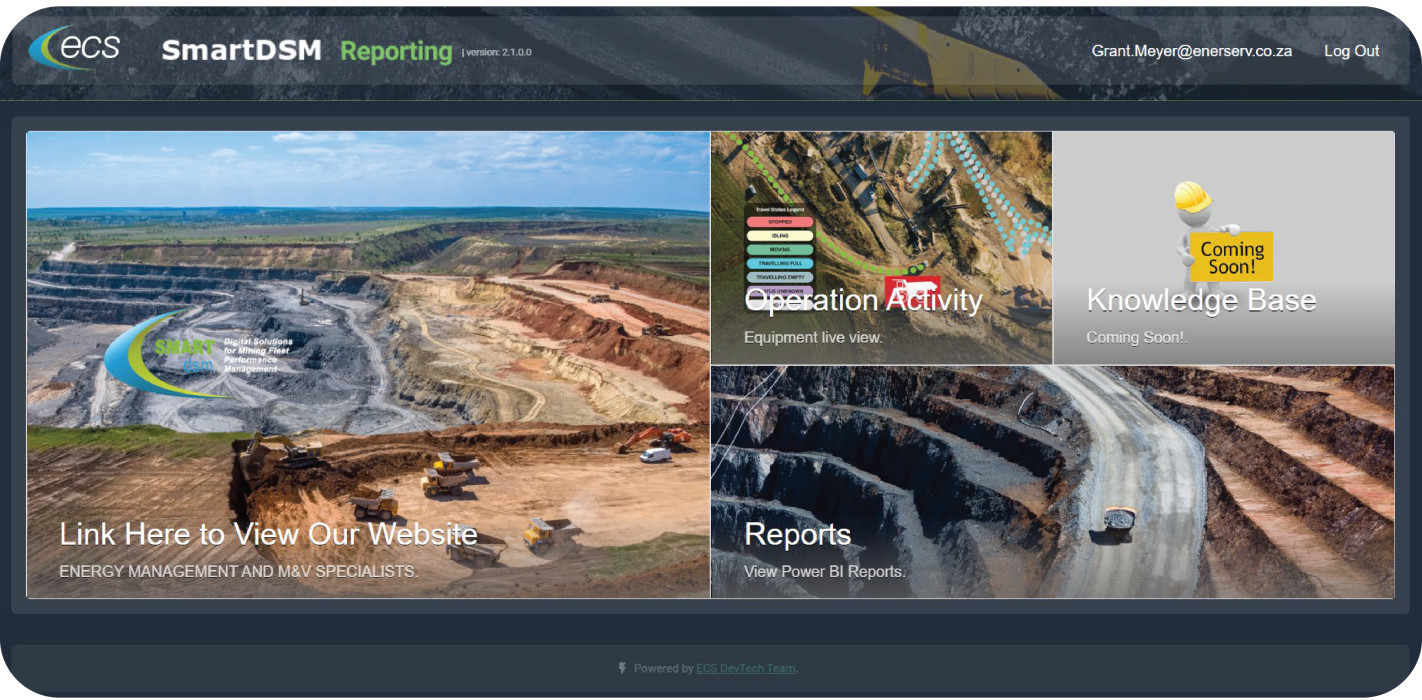

Performance Dashboards and Management Portals

SmartDSM’s Dashboard and performance reporting can be fully integrated with other

mining management systems. The integration of Power BI Summary Reports into the

SmartDSM portal facilitates a deeper understanding of the Energy and Productivity

performance of each piece of equipment.

Testimony

“We used SmartDSM to enable our managers to measure

aspects of Energy, Production, and Carbon Performance

within their control.

After implementing SmartDSM, a piece of hauling

equipment overturned on site due to driver negligence.

Through the analysis of raw equipment data and accurate

reporting, the ECS team was able to provide us with a

deep dive assessment of the driver’s behavioural patterns.

Thank you to ECS and their team for helping us improve

our production and reach our sustainability targets”

- A Major Contract Miner

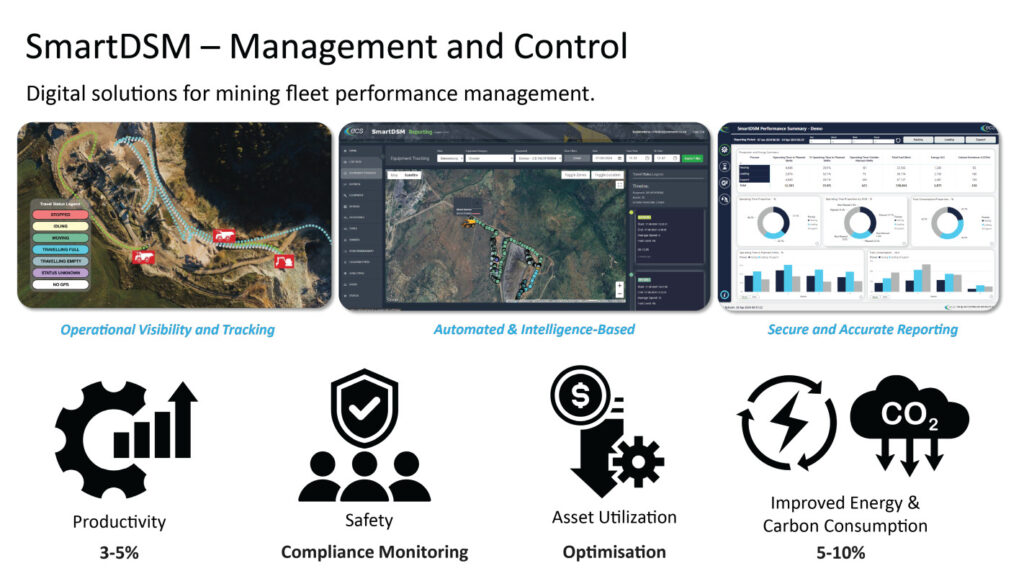

SmartDSM What does it give you?

Key Value Elements:

- Safety: Trends of these KPIs can be visualised and compliance monitored

- Productivity: 3% to 5% improvement in productivity

- Energy and Carbon: 5% to 10% improvement in energy efficiency and carbon emissions

- Asset Utilization: Optimisation of the truck and loader availability and utilization

SmartDSM - Sustainable Decision Support

SmartDSM is a cost-effective, IIoT-enabled solution that

enables sustainable decision support through:

- Production and energy data collection using IIoT-enabled technology

- Monitoring and tracking of equipment showing live location

- Load and haul cycle reporting including cycle time, payload, and distance travelled

- Expected energy and cycle time reporting to inform operational performance.

- Comparison of equipment performance within fleets.

- Energy efficiency improvement and related carbon emissions reduction

- Health and Safety compliance

SmartDSM is designed for mining operations without

sophisticated telematics systems on their equipment.

SmartDSM Live Equipment Tracking Dashboard

Geospatial View:

• Provides a real-time map displaying the location of

equipment on site, enabling easy tracking and

monitoring. Speed & Fuel Percentage:

• Current speed & remaining

fuel in the tank Current Status:

• real-time status of equipment,

indicating operating, idling,

stopped, or parked

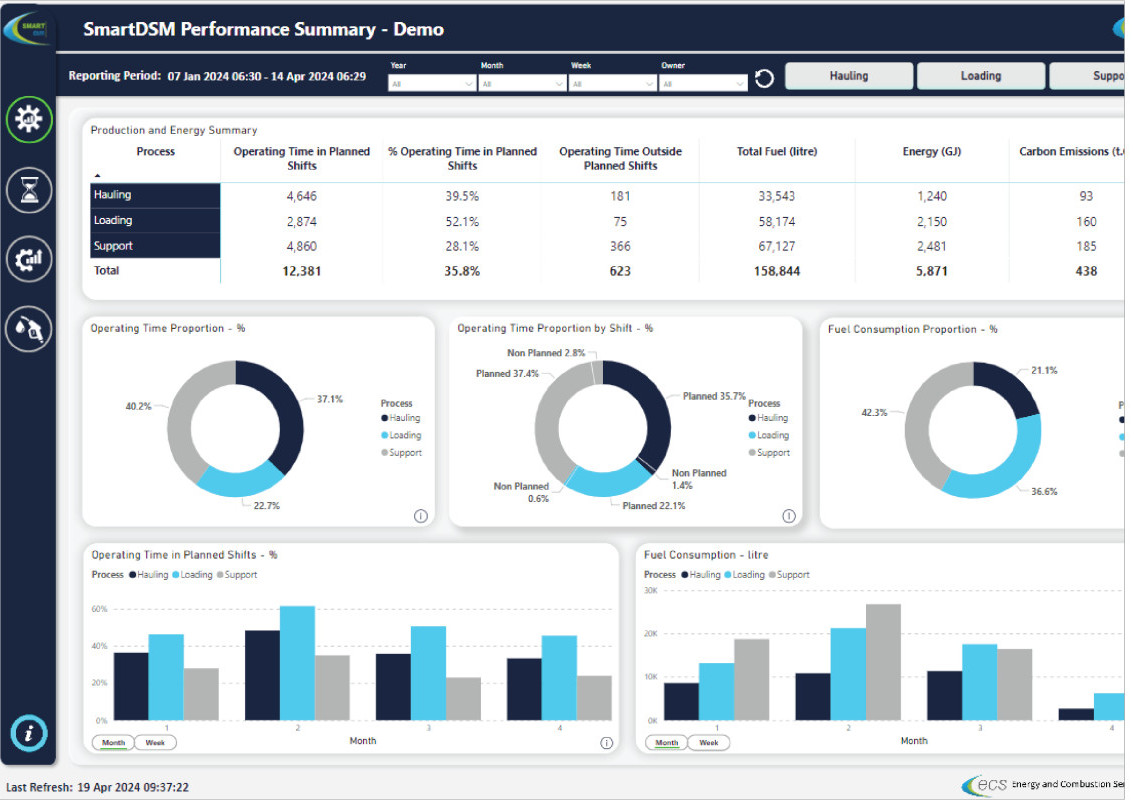

SmartDSM Reporting Performance Summary

Operating Time

Tracks how long equipment is actively

working, helping to optimize usage and

reduce downtime. Fuel

Monitors fuel consumption to control costs and improve fuel efficiency. Energy & Carbon

Measures energy usage and carbon emissions, supporting sustainability and

environmental goals.

SmartDSM Reporting Operating Time

Operating Time Breakdown:

Analyzes equipment in operation

during specific periods, providing insight into how time is spent across various tasks. Operating Inside and Outside of

Shifts:

Monitors equipment performance

both during and outside of scheduled work shifts to identify potential inefficiencies or opportunities for optimization.

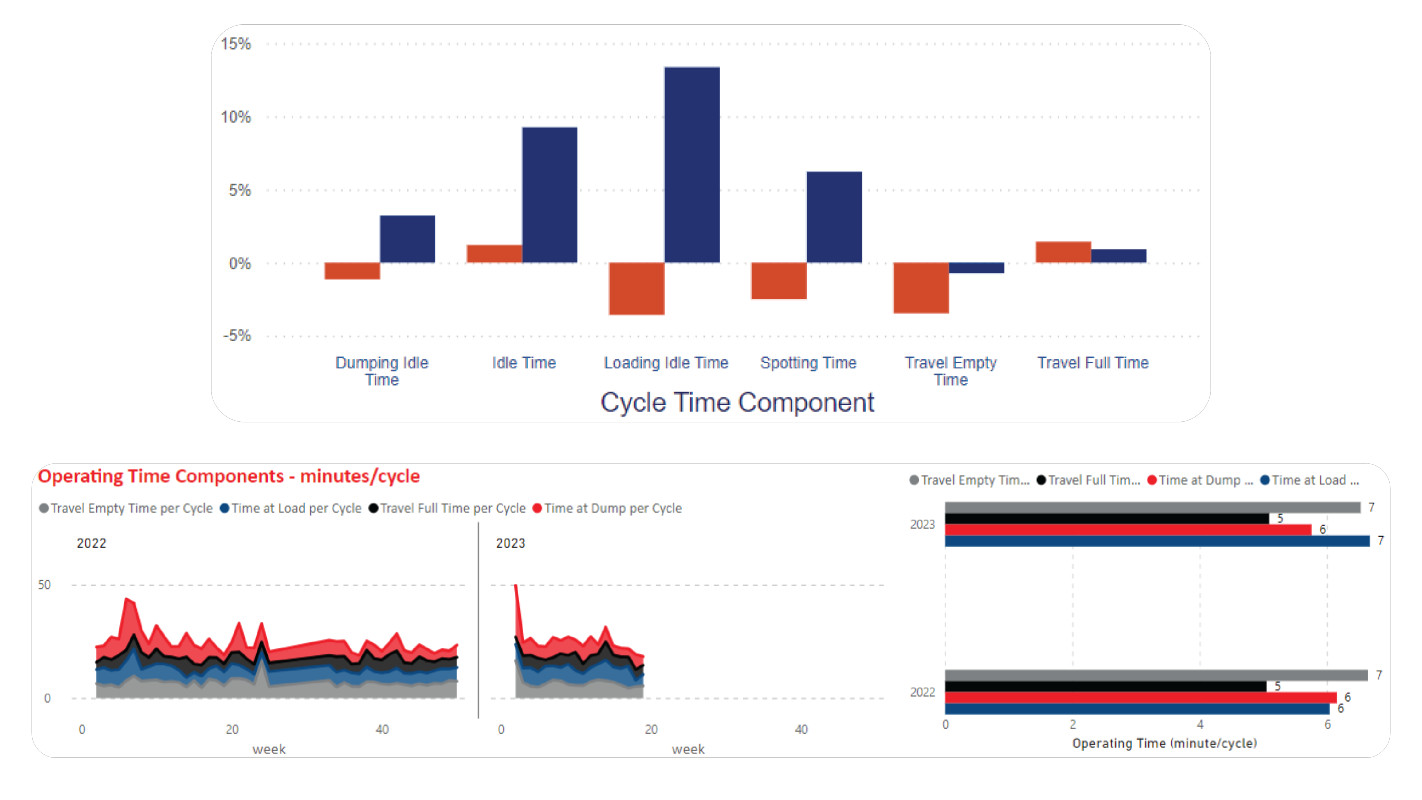

SmartDSM Reporting - Operating Time Continued

Operating Time Component Breakdown:

Categorizes equipment activity into key phases: idle

time, travel full, travel empty, loading, and other

operational tasks. This breakdown helps pinpoint

inefficiencies in specific processes. Temporal/Comparative Performance:

Tracks equipment performance over time, comparing

it across different periods (e.g., daily, weekly,

monthly) to identify trends, deviations, and areas for

improvement.

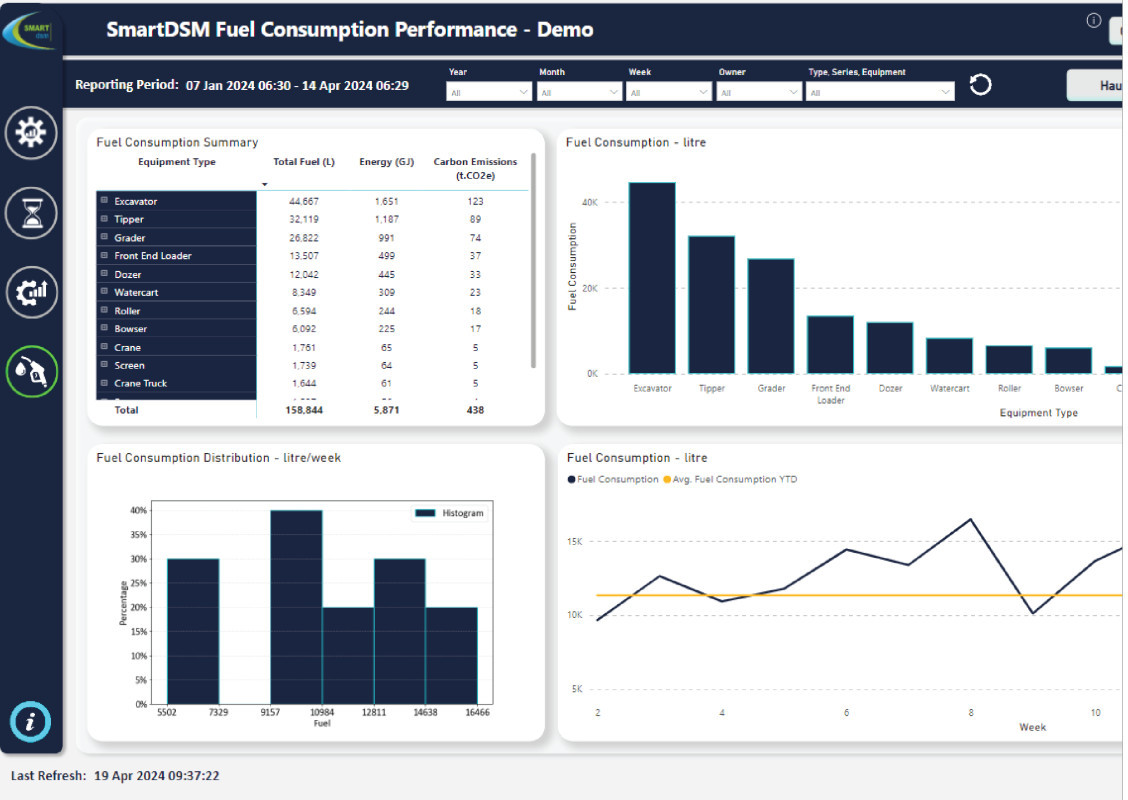

SmartDSM Reporting Fuel Analysis

Total Fuel Consumption by Equipment:

Measures the overall fuel used by each piece of equipment, aiding in cost control

and resource management. Temporal/Comparative Performance:

Tracks equipment performance over time, comparing it across different periods (e.g. daily, weekly, monthly) to identify trends, deviations, and areas for improvement.

SmartDSM Reporting - Fuel Analysis Continued

Fuel Energy Intensity:

Tracks the energy output per unit of fuel consumed, helping evaluate the efficiency

of fuel usage. Burn Rate:

Monitors the rate at which fuel is consumed during operation, providing insights into equipment efficiency and

performance. Fuel per Cycle:

Calculates the amount of fuel used per operational cycle, enabling performance benchmarking and optimization.

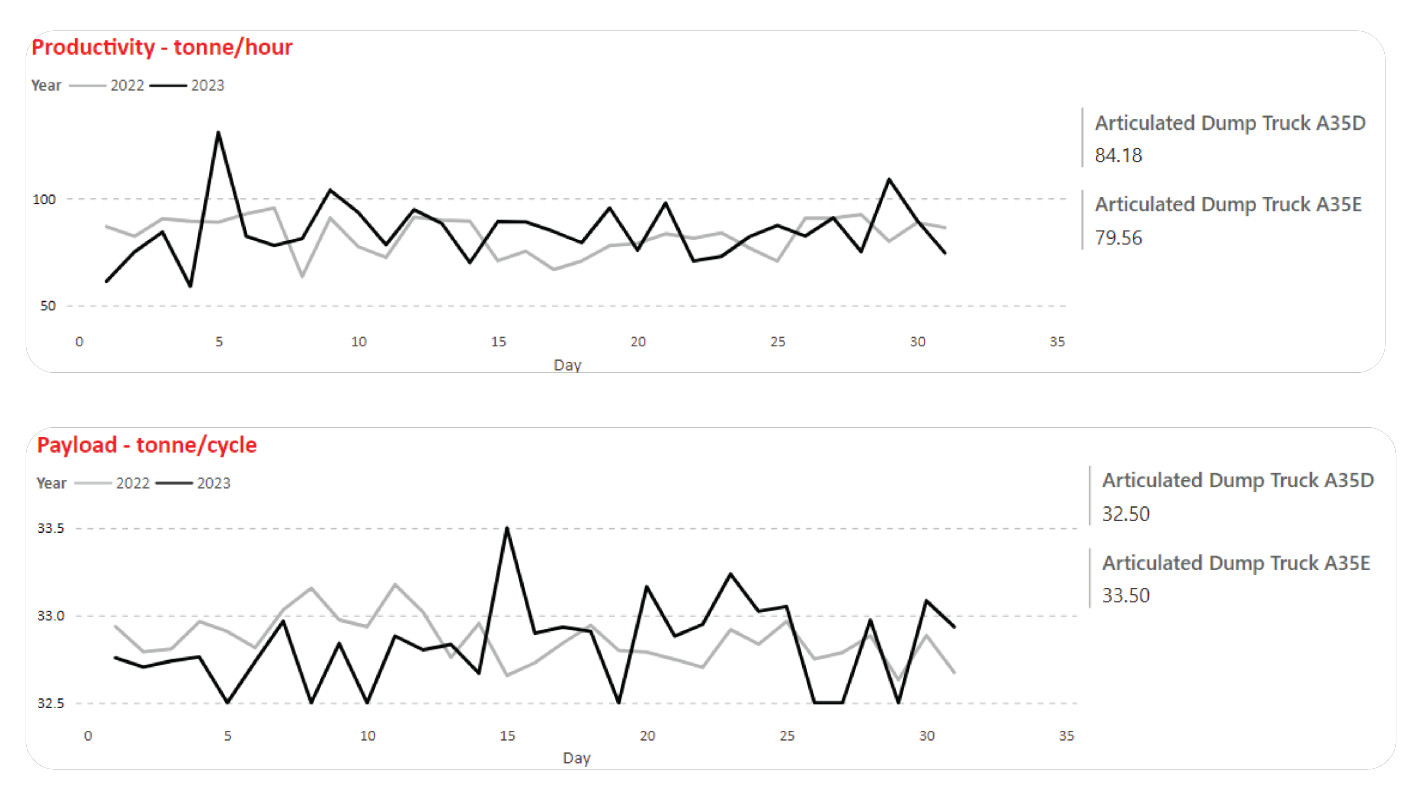

SmartDSM Reporting - Production & Operating Efficiency

Productivity:

Measures the amount of

material moved per hour,

providing insights into

equipment productivity and

efficiency. Payload:

Tracks the weight of material

carried per load, helping assess

equipment capacity utilization. Temporal/Comparative:

Compares productivity metrics

over different periods (e.g.

daily, weekly) to identify trends, performance improvements, or

declines.

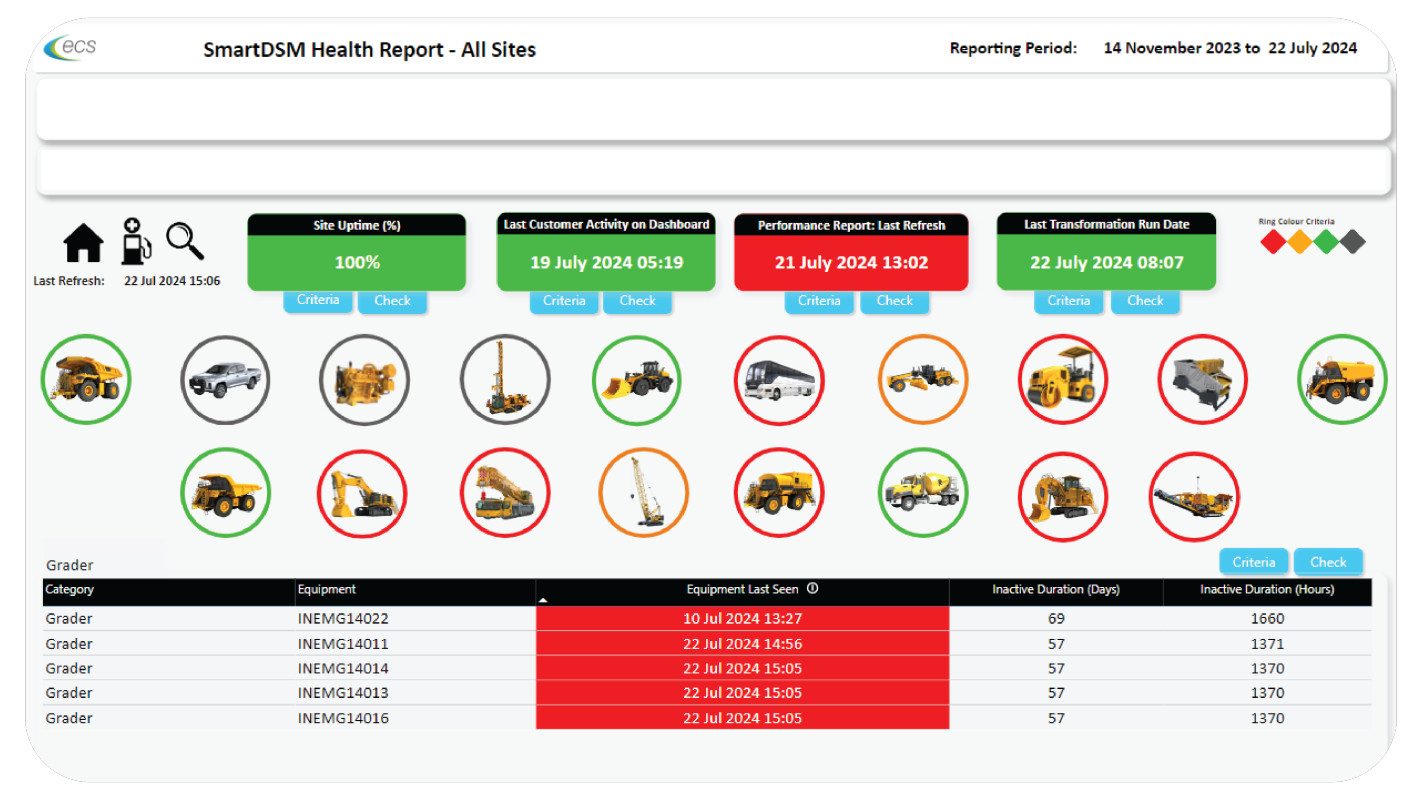

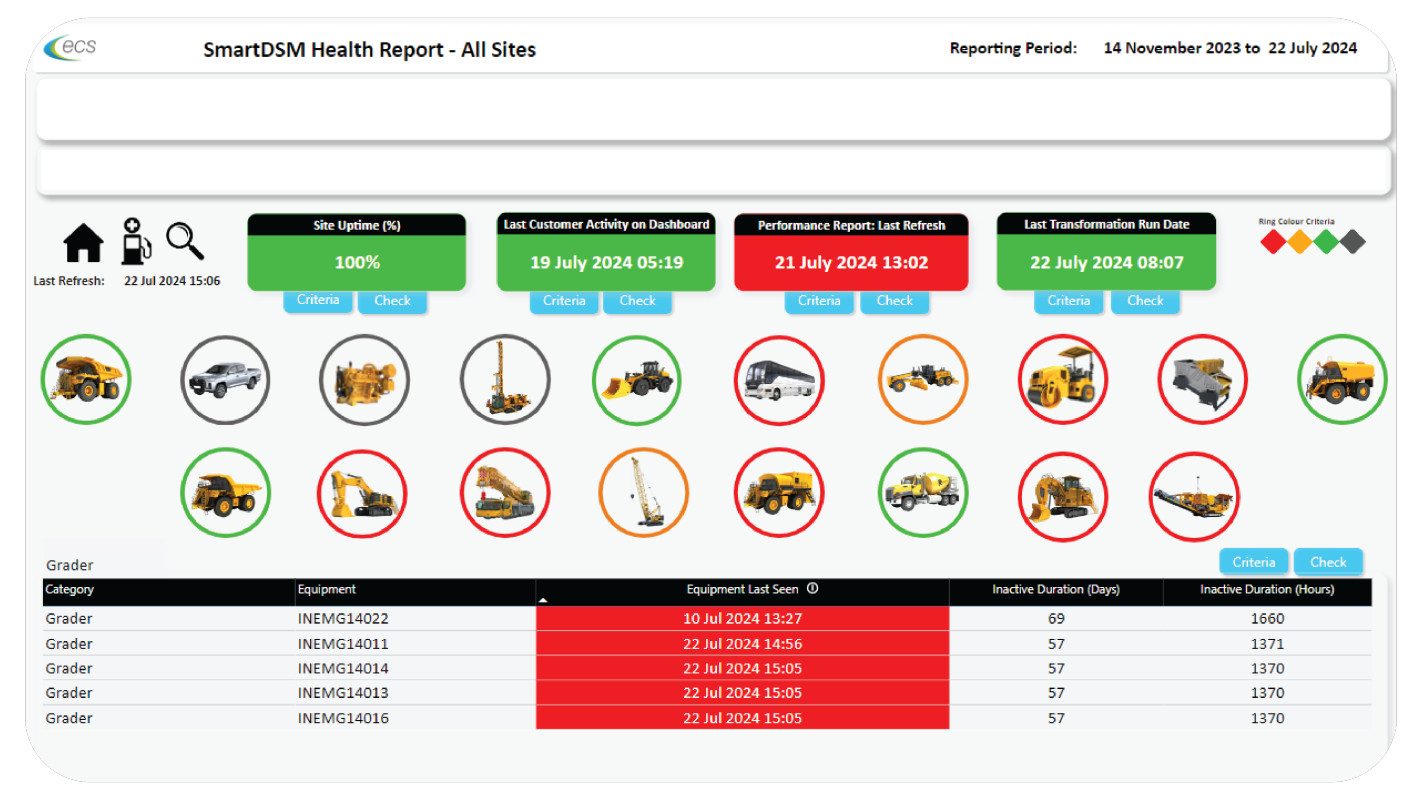

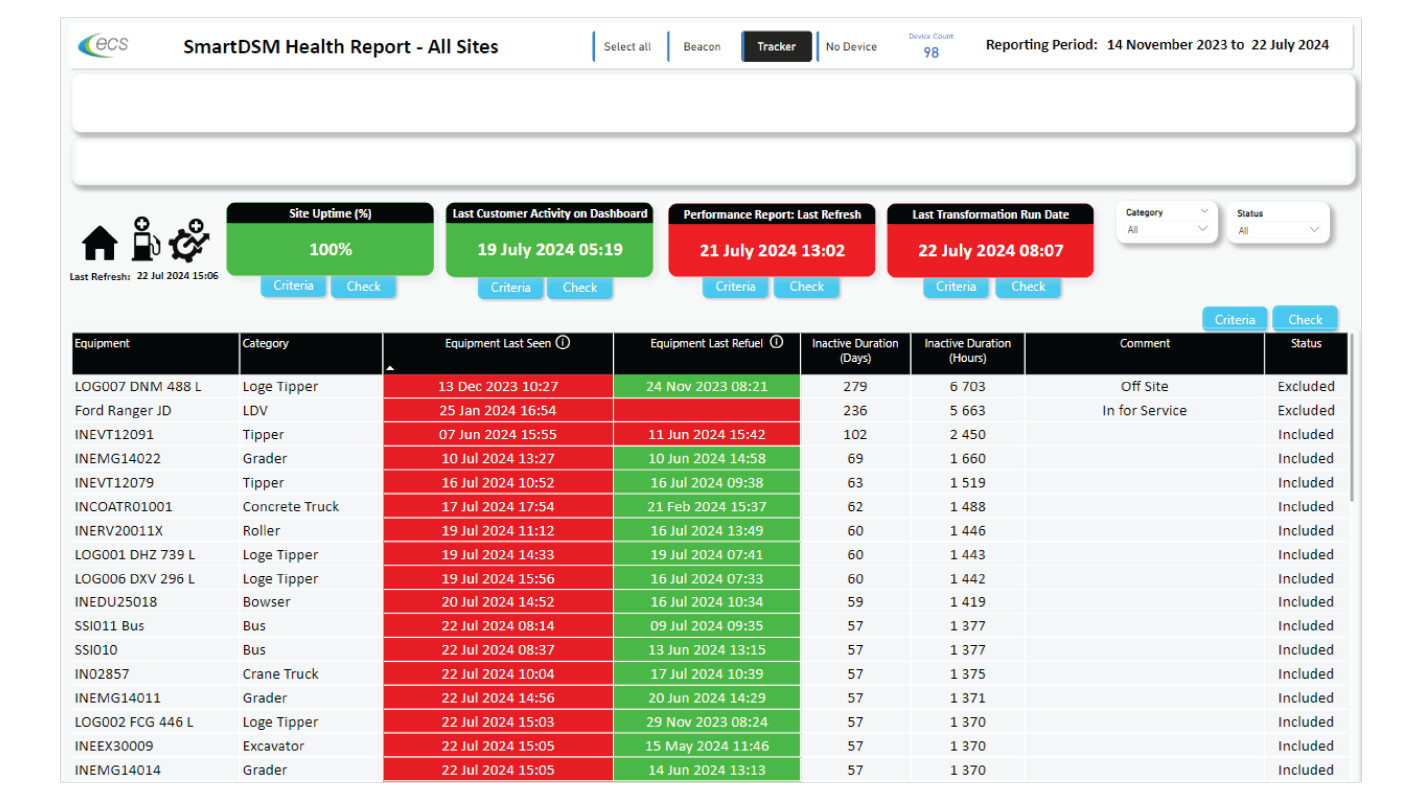

SmartDSM System Health Monitoring

The DSM System Health Report is engineered to focus on monitoring equipment activity with the sole objective of

guaranteeing the effectiveness and precision of trackers. This empowers users to proactively monitor equipment

performance and maintain operational efficiency.

SmartDSM System Health Monitoring

The DSM System Health Report is engineered to focus on monitoring equipment activity with the sole objective of

guaranteeing the effectiveness and precision of trackers. This empowers users to proactively monitor equipment

performance and maintain operational efficiency.

SmartDSM System Health Monitoring Criteria

- 1. Site Uptime: Measures how long the system or site has been operational without interruptions.

- 2. Last Customer Activity: Records the most recent interaction or activity from customers using the system.

- 3. Performance Report Last Refresh: Tracks when the last performance report was updated to ensure data is current.

- 4. Transformation Last Run: Indicates the most recent time data transformations (like ETL processes) were executed successfully.

- 5. Equipment Last Seen: Logs the last time a specific piece of equipment reported status, showing active connectivity.

- 6. Equipment Last Refuel: Captures the most recent refuelling event for equipment to track operational readiness.