The SmartFEMS Solution

ECS’s automated SmartFEMS Solution ensures that every aspect

of refueling is managed, controlled, and reported on.

SmartFEMS automatically performs authorisation checks on

each piece of equipment before allowing fuel to be dispensed.

Remote delivery of fuel on site can also be controlled via the

same logic and computational process.

As an added layer of security, authorisation checks and vehicle

proximity checks are conducted before allowing fuel to be

dispensed.

SmartFEMS enables:

- Automatic capturing of all fuelling transactions

- Automatic vehicle identification

- Limitation of unauthorised fuelling

- Elimination of tag-based and nozzle-in-tank equipment

- Minimal physical interaction between the user and the operating solution

- Live tank level reading of bulk storage facilities and equipment in use

- Automatic capturing of equipment run hours and actual equipment whereabouts

- Permission to dispense fuel/lubricant into identified equipment based on proximity awareness to the fuelling bay

- Permission to dispense fuel/lubricant into identified equipment based on equipment burn rate and operating activities

- Dynamic inventory management and reporting

- Real-time fuel discrepancy alerting

- SARS on Road Fuel Levy Refund Reporting

Performance Dashboards and Management Portals

The integration of Power BI Summary Reports into the SmartFEMS portal facilitates a deeper

understanding of the fuelling activity for each piece of equipment.

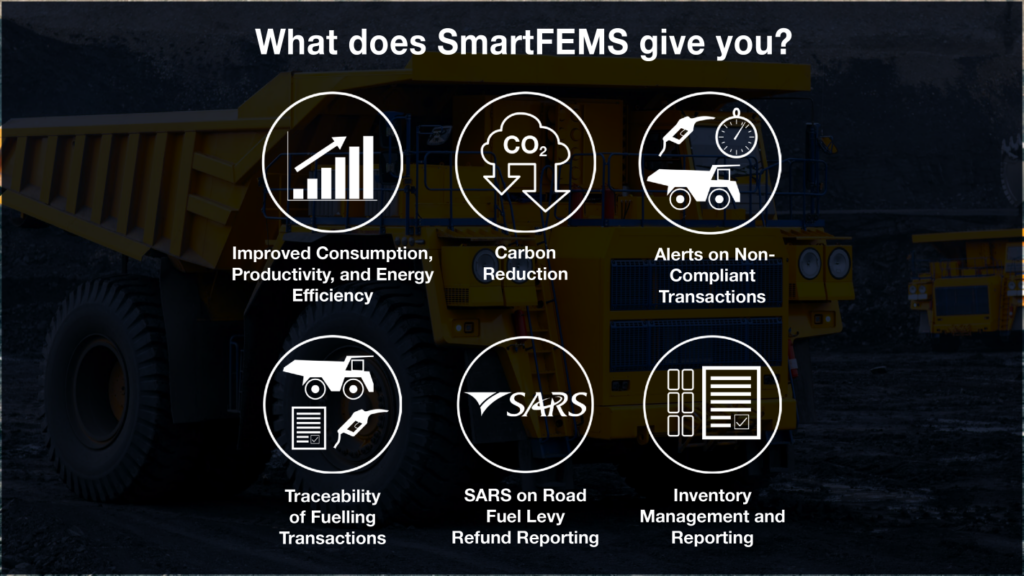

SmartFEMS What does it give you?

Key Value Elements:

- 20% to 30% Unaccounted Fuel Improvement

- Restricted Human Intervention with the System

- Intelligence-Driven System for Optimal Efficiency

- Realtime Exception Alerts

- Limited System Maintenance Costs

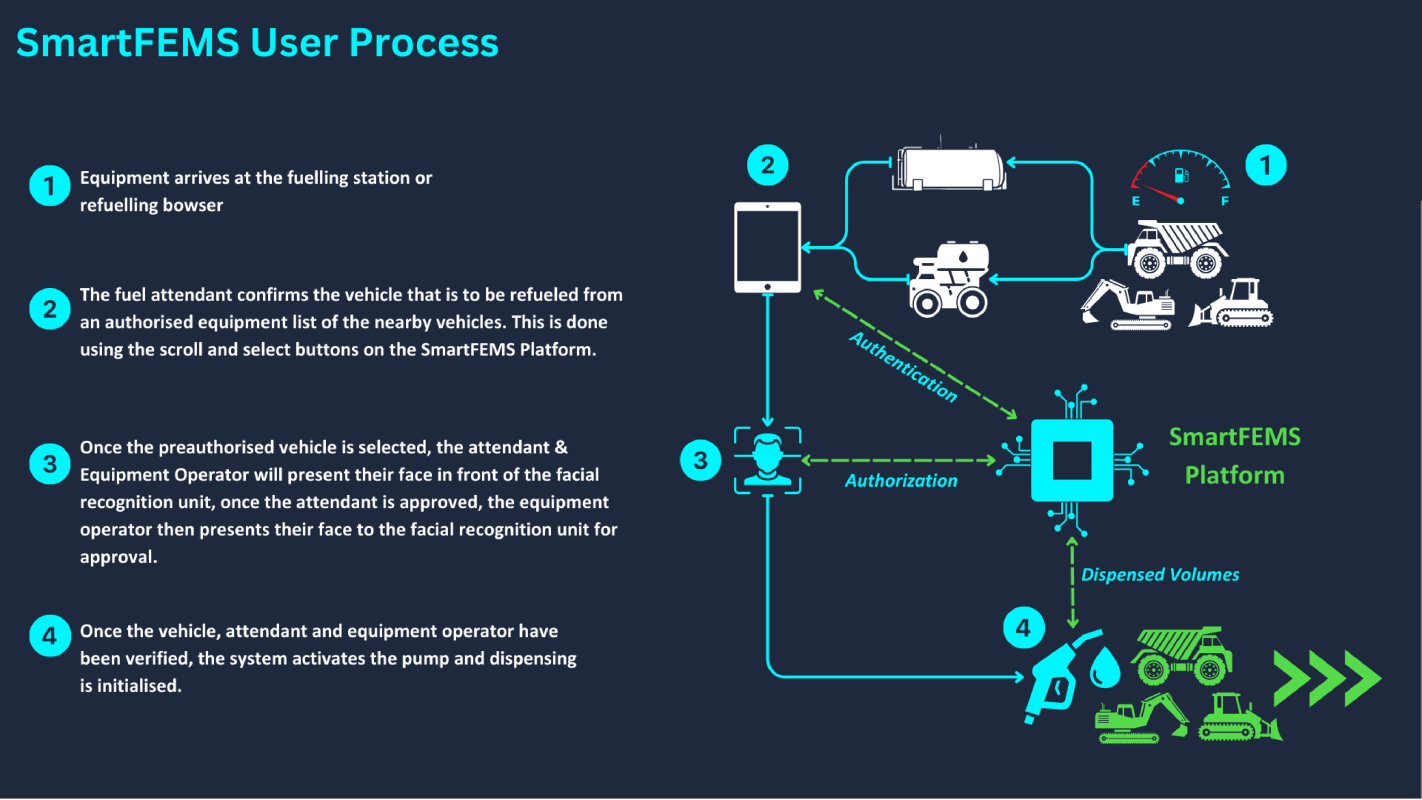

The SmartFEMS Solution

- ECS's SmartFEMS Solution manages, controls and reports from inventory through to the in-use of fuel.

- SmartFEMS performs authorization authentication checks of the attendant, equipment operator and equipment before allowing fuel dispensing (refuelling stations and bowsers).

- SmartFEMS automatically controls the dispensing pump based on the fuel required for actual work done (based on agreed refuelling standards)

- SmartFEMS is fully functional off-line (no internet required to be operationally functional)

The SmartFEMS Solution Enables

- Automatic capturing of all fuelling transactions

- Automatic vehicle identification

- Limitation of unauthorised fuelling

- Elimination of tag-based and nozzle-in-tank equipment

- Minimal physical interaction between the user and the operating solution

- Live tank level reading of bulk storage facilities and equipment in use

- Automatic capturing of equipment run hours and actual equipment whereabouts

- Permission to dispense fuel/lubricant into identified equipment based on proximity awareness to the fuelling bay

- Permission to dispense fuel/lubricant into identified equipment based on equipment burn rate and operating activities

- Dynamic inventory management and reporting

- Real-time fuel discrepancy alerting

- SARS Diesel Refund System Reporting:

- The diesel levy currently applicable amounts to R3.66 per litre

- Charged in the purchase price of the fuel

- 80% of eligible diesel purchases qualify for the refund

- SARS refund logbook requirements to be fully met

- The diesel levy currently applicable amounts to R3.66 per litre

Why Do You Need SmartFEMS

SmartFEMS addresses the following challenges:

Fuel & lubricant Management System:

- Misallocation of fuel transactions

- Missing fuelling transactions

- Miscellaneous fuelling transactions

Work Done by Piece of Equipment (Where production data is available):

- Establishing that work done (tonnes moved) by each piece of eligible equipment is matched to the fuel transactions

- Generation of work profiles (statistical) and data models for tracking equipment work done with batched fuelling

transactions

Matching Critical Transactional Data Sets (Where production data is available):

- Missing transactional events for both fuel or production data sets

- No accurate matching of the fuel transaction to the actual tonnes moved

- No effective matching of the kilometre or run hour meter data with both the fuelling or production transaction data sets

- No kilometre or run hour meter data for each piece of equipment for work done

Measurement of System Health:

- No fuel meter and tank gauging serviceability and calibration record keeping system with notifications

- No tracking of TFM equipment serviceability with notifications

- No System Health performance monitoring, corrective action and reporting

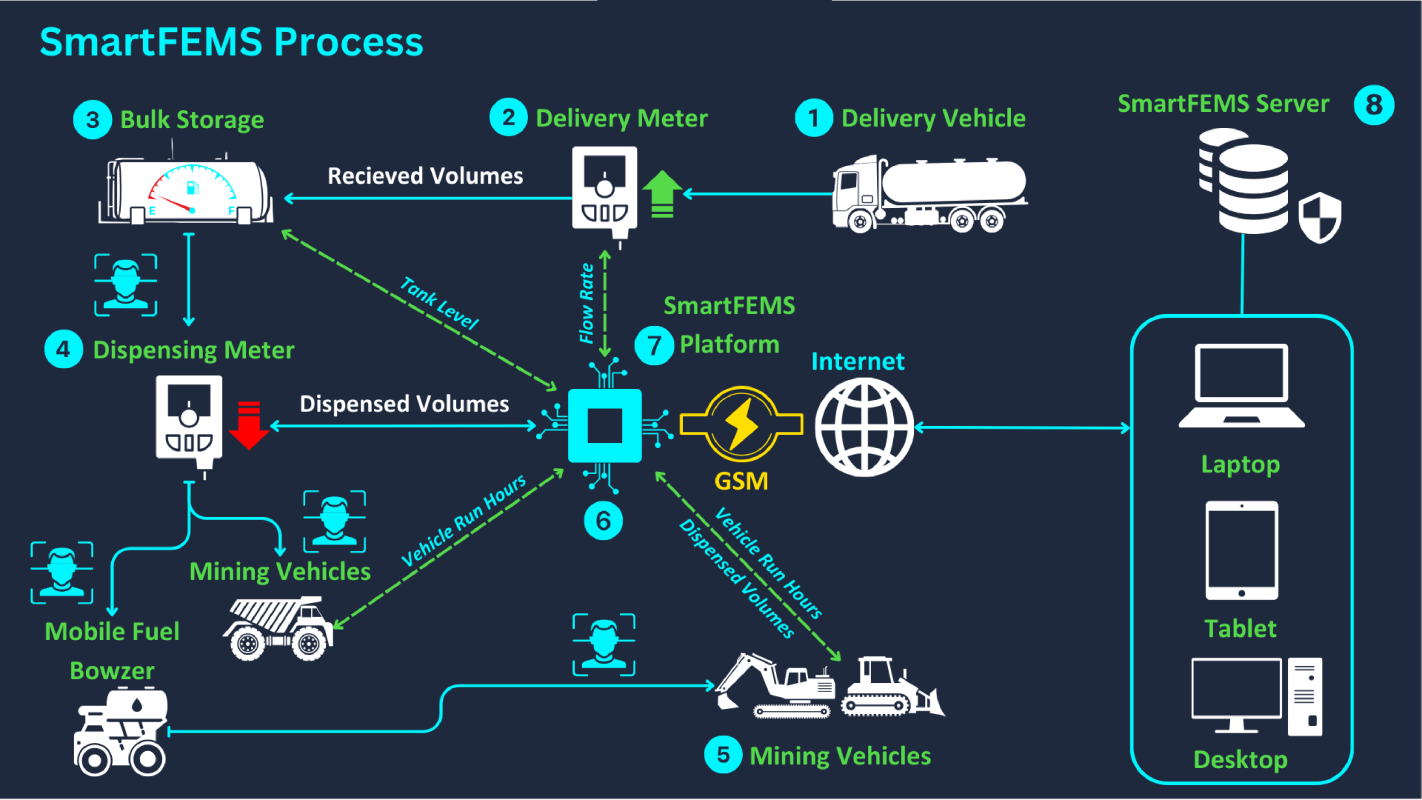

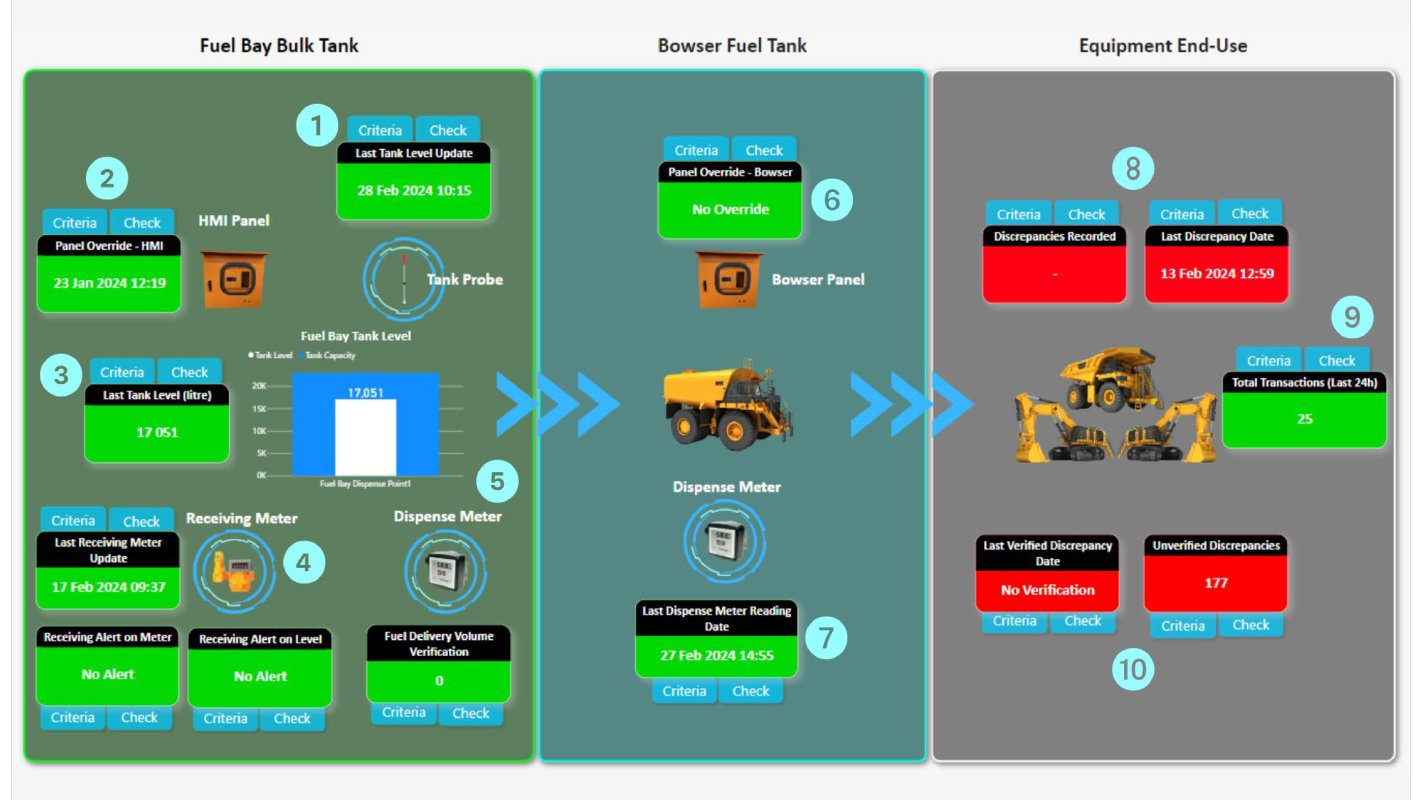

SmartFEMS Process

SmartFEMS Fuel Management Reporting

- Offers a detailed overview and valuable insights into the fuelling operations within the business.

- The report serves as a tool to monitor and track fuel consumption across on-site assets, including trucks, generators, LDVs, and more.

- The overview illustrates the refuelling process from the refuelling bay to the asset tanks, while the insights delve into specifics such as identifying the primary fuel consumer among the assets, tracking engine hours, and determining the tanks that refuel the assets most frequently.

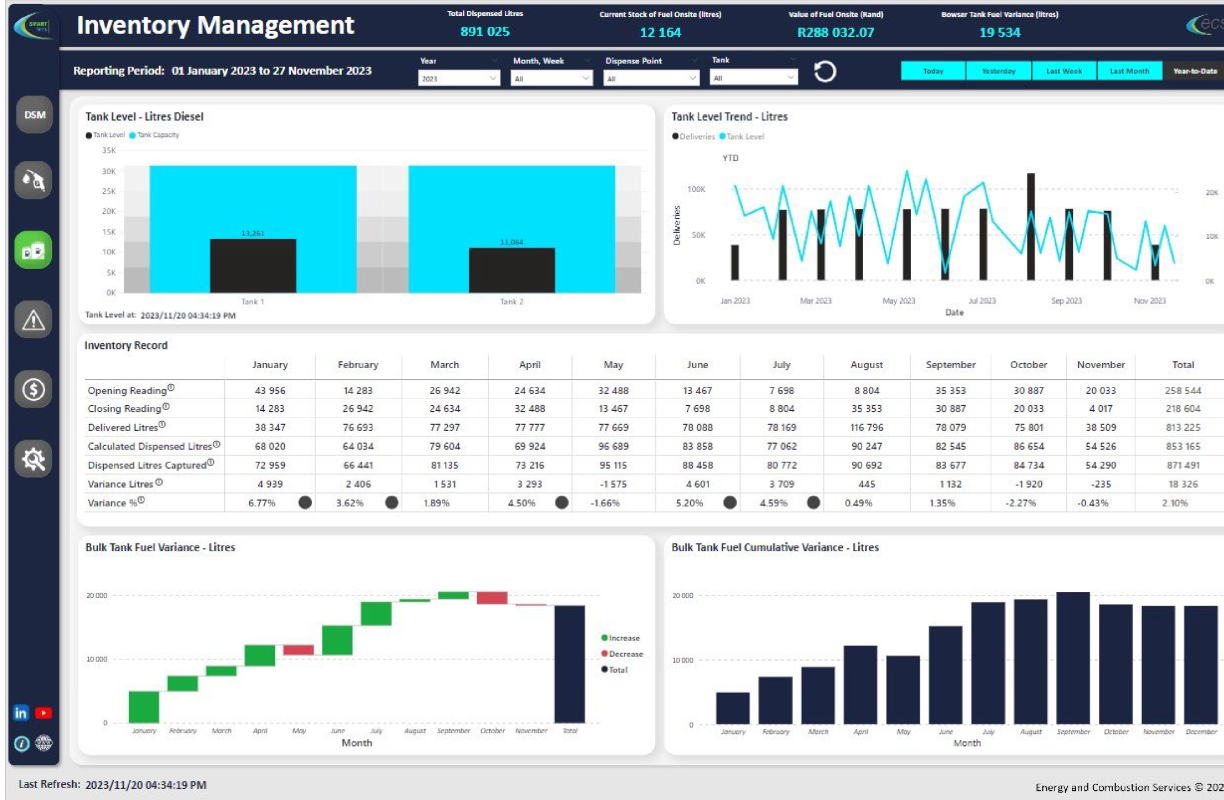

SmartFEMS inventory Management Reporting

- Offers a comprehensive summary of fuel tank levels and trends within a specific period.

- Enables the user to effectively monitor their fuel inventory, while facilitating well-informed decisions regarding the purchase of fuel for their operation as well as visibility of fuel reconciliation.

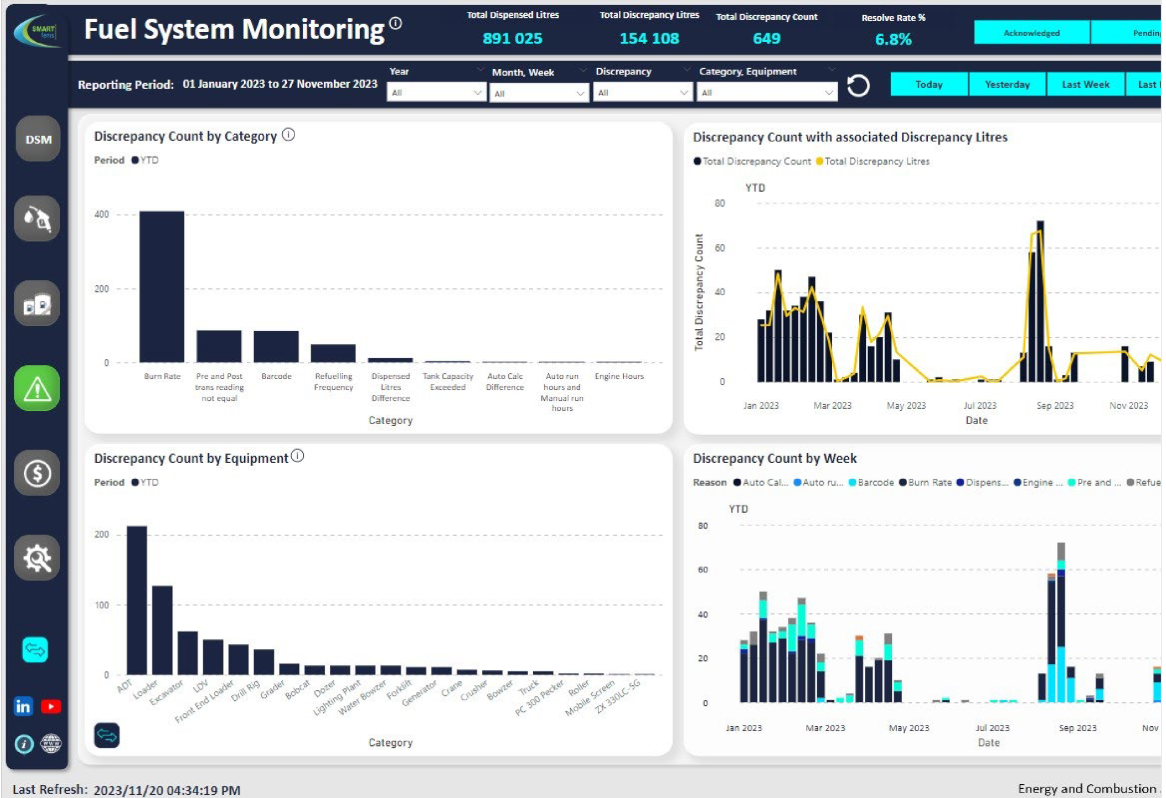

SmartFEMS Fuel System Monitoring Reporting

- Fuel System Monitoring highlights the number of transactions and overall fuel in litres that have been flagged due to discrepancies within the refuelling operation.

- These discrepancies encompass scenarios like surpassing burn rates and tank capacities, as well as instances where assets exhibit a high frequency of refuelling to name a few. Users can utilize this report to oversee and enhance their refuelling operations by addressing potential issues, ultimately contributing to increased efficiency within their refuelling operation.

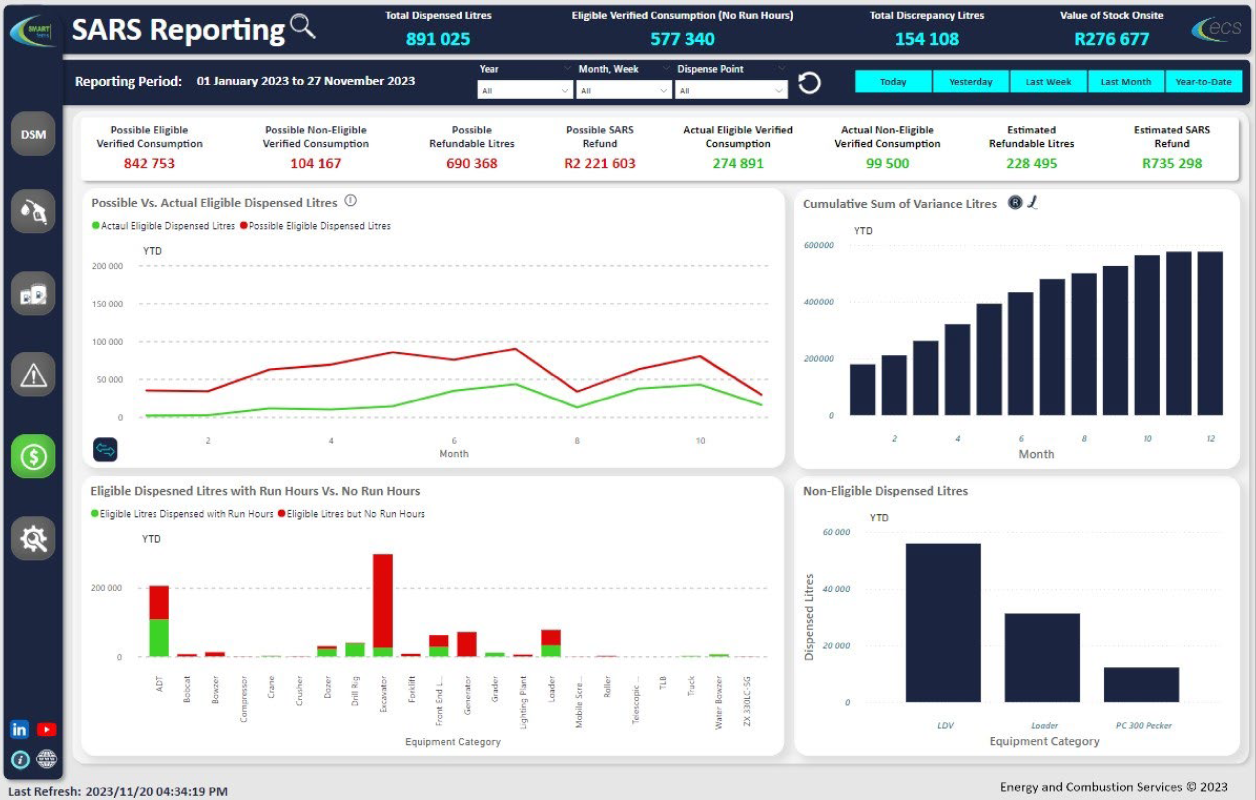

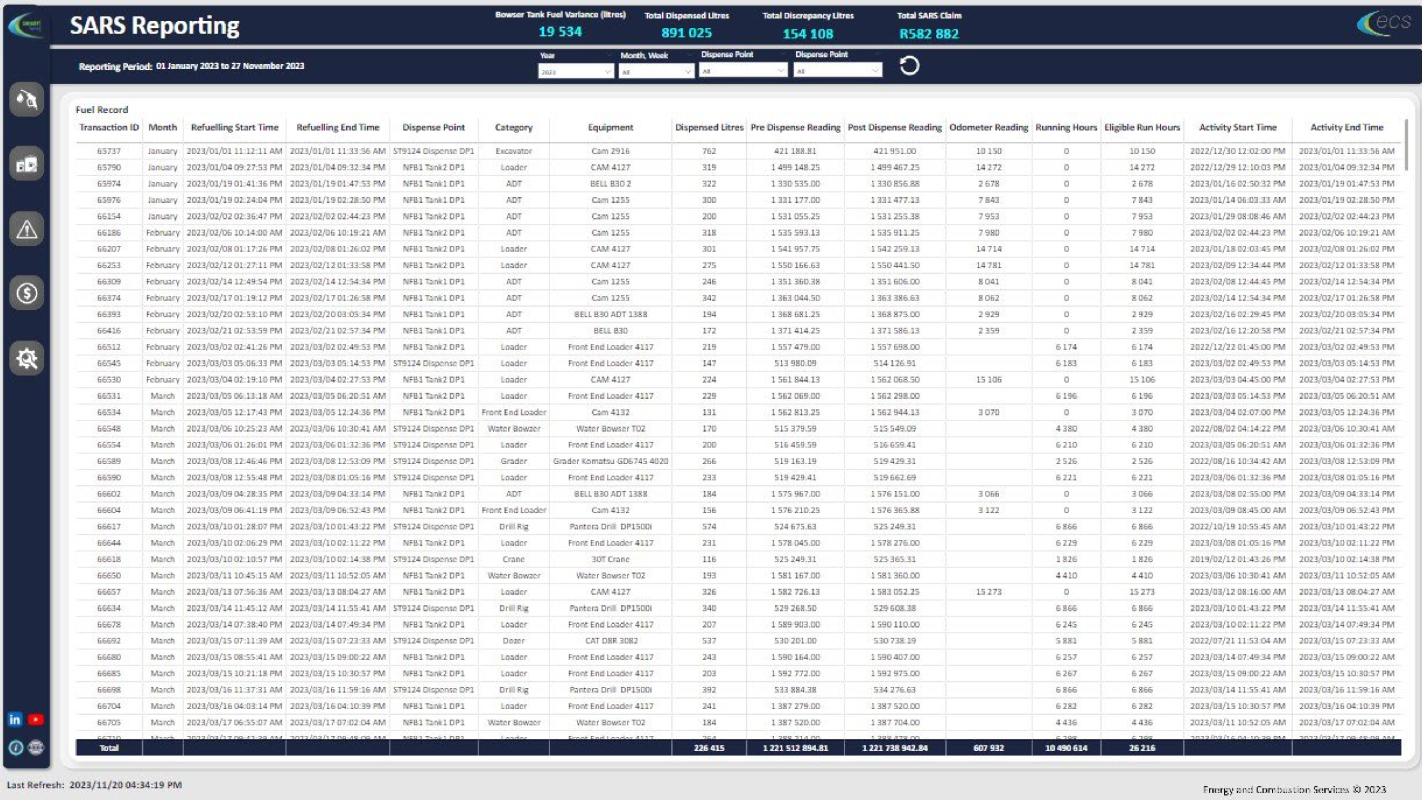

SmartFEMS SARS Reporting

SARS Reporting provides comprehensive information on the eligibility of the assets that are valid for a SARS refund. It

enables the user to get insights into their eligible and non-eligible assets in litres while providing an estimated rand

value of the eligible assets. It also provides proof of operational data (Fuel used against matched Run Hours) of these

assets which is a requirement of the SARS refund claim where the user has access to a full, comprehensive but tailored

view of the relevant data.

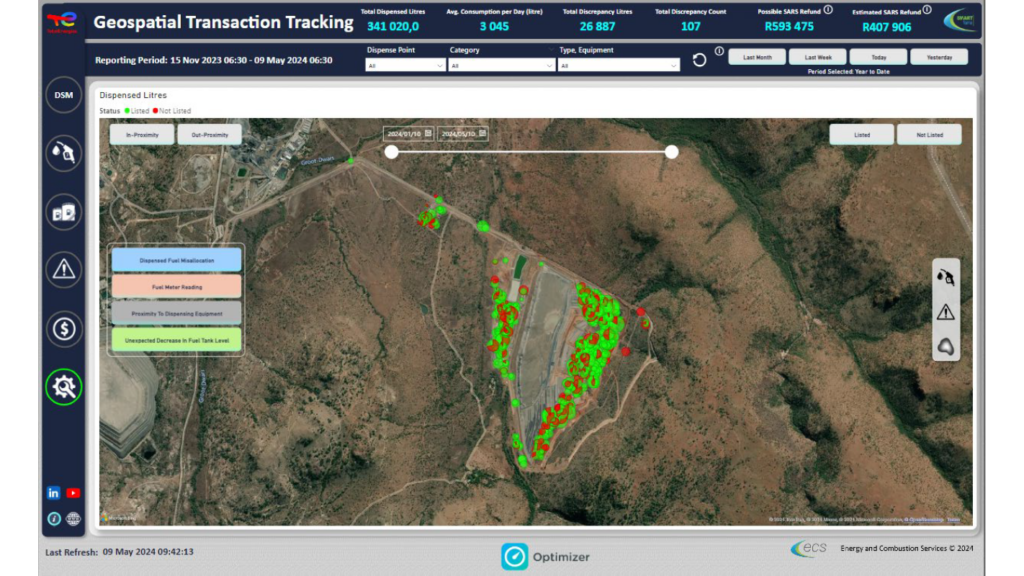

SmartFEMS Reporting - Geospatial Transaction Tracking

Geospatial tracking offers users three interactive map views that enhance operational insights.

The first map highlights transactions

and fuel received by each piece of

equipment, providing clear visibility

into the locations and timings of

these activities.

The second map identifies discrepancies

across the site, detailing the associated

equipment and fuel volumes.

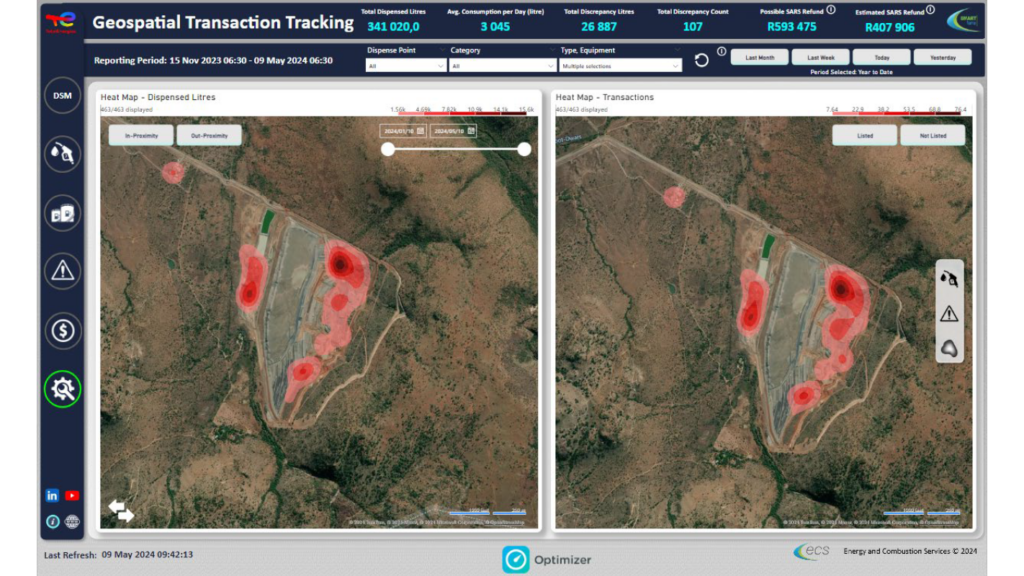

The third map is a heatmap

visualizes transaction volumes,

dispensed litres, and discrepancy

hotspots – offering a comprehensive

overview of operational efficiency

and potential issues.

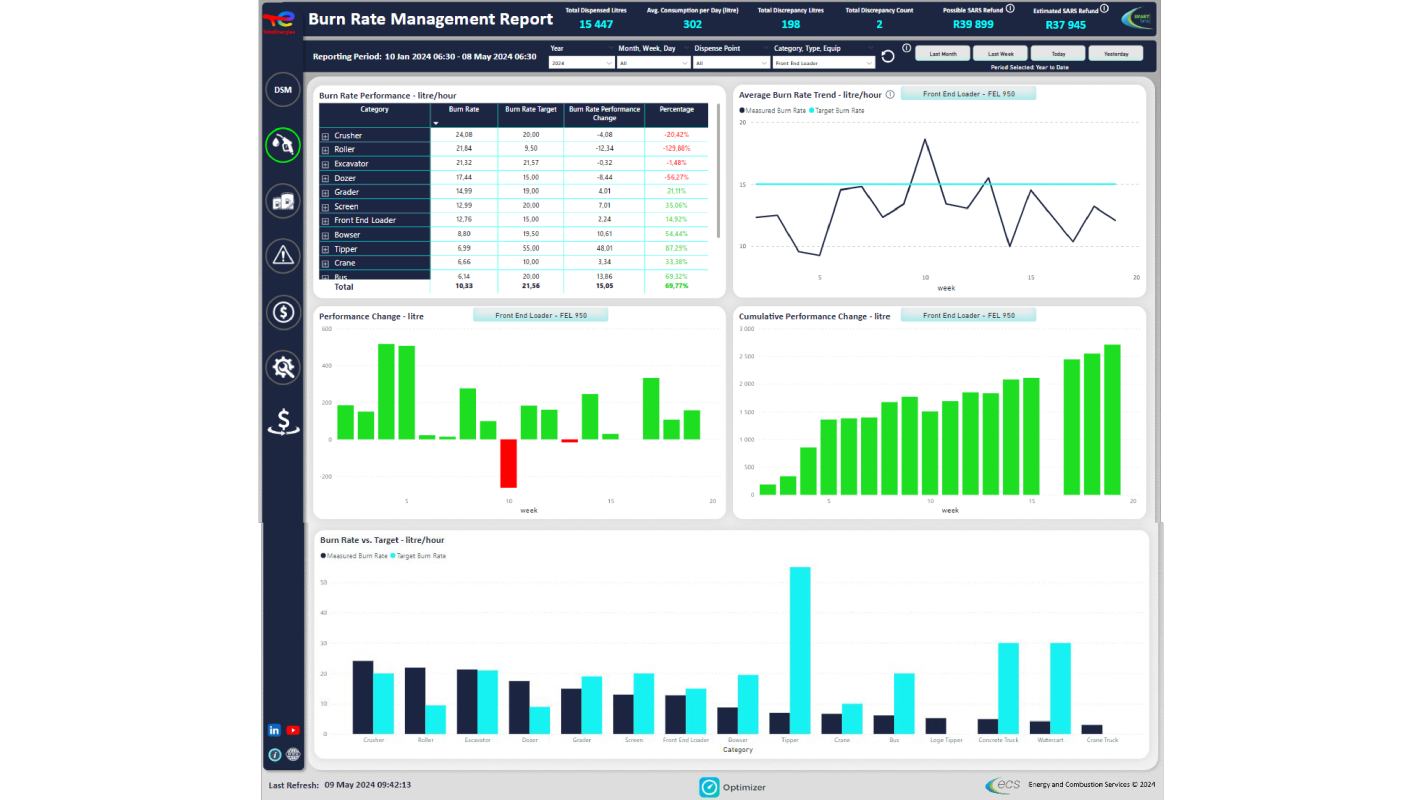

SmartFEMS Burn Rate Management Reporting

- Provides a detailed analysis of equipment efficiency by illustrating burn rates based on run hours and litres consumed on site.

- By comparing actual burn rates against target values for each piece of equipment, this system enables the tracking of performance trends and year-to-date actuals.

- This comparison helps identify underperforming equipment, optimize fuel consumption, and enhance overall operational efficiency.

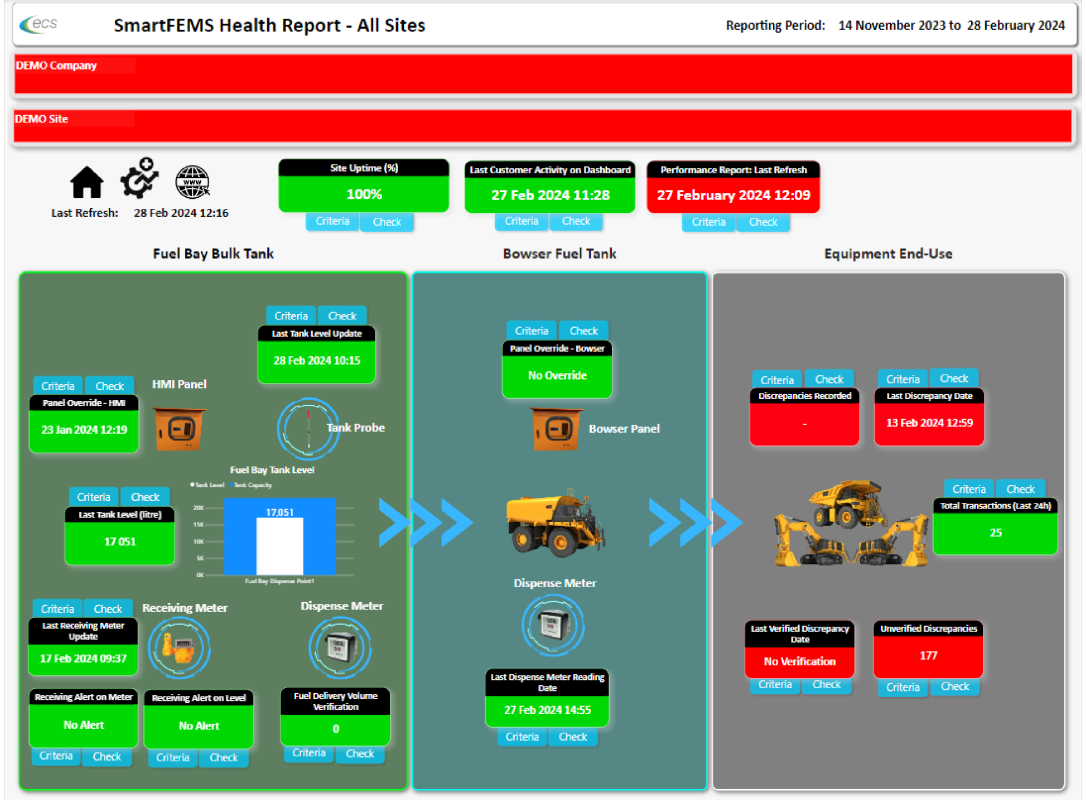

SmartFEMS System Health Monitoring Reporting

The system metering and gauging health status is remotely monitored in real-time with automated alerts and

notifications for investigation and maintenance action.